Why Small Laser Welding Machines Are in High Demand

News 2022-06-14

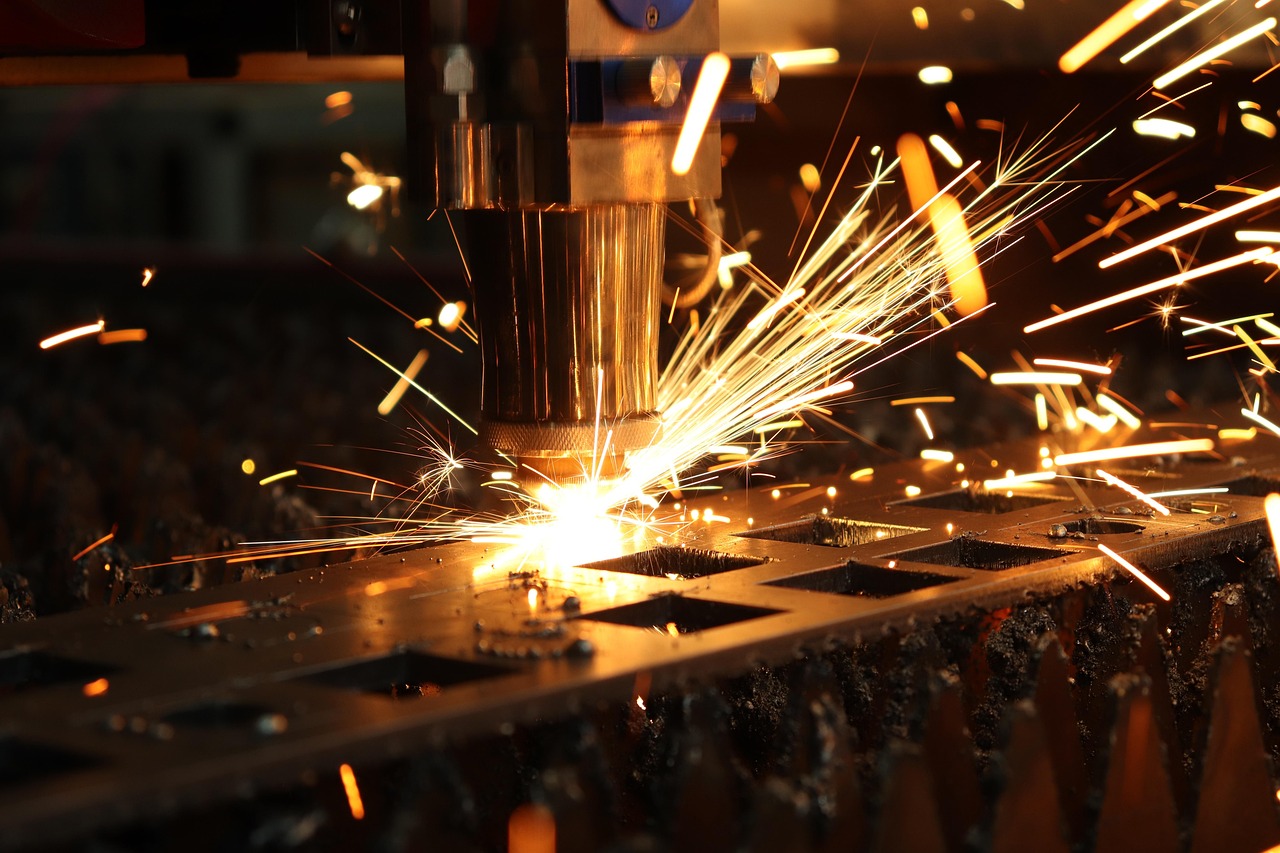

In recent years, laser welding technology has moved beyond large industrial production lines and entered workshops, repair centers, and small manufacturing businesses. One of the most important drivers of this shift is the growing availability of the small laser welding machine and the handheld laser welder.

Compared with traditional welding methods, laser weld technology offers faster speed, higher precision, and cleaner weld seams. For many users, understanding the small laser welding machine price, real-world performance, and return on investment is now a key decision factor.

This article provides a complete, practical guide to laser welding—explaining how handheld laser welders work, what affects laser weld quality, how prices are structured, and how to choose the right system for your specific needs.

What Is a Small Laser Welding Machine?

A small laser welding machine is a compact laser welding system designed for flexible operation and moderate power output. Unlike large automated laser welding stations, small systems are optimized for portability, manual control, and cost efficiency.

Most modern small laser welding machines use fiber laser technology, which offers excellent beam quality, high energy efficiency, and long service life. When combined with a handheld welding gun, these machines allow operators to perform precise laser welds on a wide range of metal parts.

Typical Characteristics

- Compact footprint

- Handheld or semi-portable design

- Moderate laser power suitable for thin to medium materials

- Easy parameter adjustment

- Low maintenance requirements

Understanding Laser Weld Technology

How Laser Welding Works

A laser weld is created by focusing a high-energy laser beam onto a metal joint. The concentrated energy rapidly heats and melts the base material, forming a molten pool. As the laser moves along the seam, the molten metal solidifies to create a strong, precise weld.

Laser welding can operate in two main modes:

- Conduction welding for thin materials and surface-level joints

- Keyhole welding for deeper penetration and stronger welds

Handheld laser welders give operators direct control over the weld path while maintaining the advantages of laser precision.

Why Laser Welds Are Different

Compared to traditional arc welding, laser welds offer:

- Smaller heat-affected zones

- Minimal distortion

- High dimensional accuracy

- Smooth, visually clean weld seams

These characteristics make laser welding especially suitable for precision applications.

Handheld Laser Welder: Design and Advantages

A handheld laser welder is the most popular configuration for small laser welding machines. Instead of fixed automation, the operator manually guides the laser welding gun.

Key Benefits of Handheld Operation

1. Flexibility and Accessibility

Handheld laser welders can reach complex joints, corners, and irregular shapes that are difficult for fixed systems.

2. Faster Setup Time

There is no need for complex fixtures or tooling, which is ideal for custom work and small batch production.

3. Lower Training Barrier

Compared to TIG welding, laser welding is easier to learn, allowing operators to achieve consistent results more quickly.

4. High Weld Quality

Even with manual operation, laser welds remain clean and uniform due to precise energy control.

Small Laser Welding Machine Price: What Buyers Should Expect

One of the most common questions from buyers is about small laser welding machine price. Prices vary widely depending on configuration, power level, and system quality.

Typical Price Ranges

-

Entry-level small laser welding machine:

USD 3,000 – 5,000 -

Mid-range handheld laser welder:

USD 4,000 – 7,000 -

Professional portable laser welding system:

USD 5,000 – 12,000+

These ranges reflect general market conditions and should be used as a reference rather than exact pricing.

What Influences Small Laser Welding Machine Price?

1. Laser Power and Stability

Higher laser power allows deeper penetration and faster welding but increases cost. For many thin metal applications, moderate power is sufficient.

2. Laser Source Technology

Fiber laser sources are the most common choice due to their efficiency and durability. Source quality plays a major role in overall system price.

3. Cooling System

Air-cooled systems are more affordable and portable, while water-cooled systems support longer duty cycles and higher power levels.

4. Control System and Interface

Advanced control panels, preset welding parameters, and user-friendly interfaces add value but also affect cost.

5. Safety and Protection Features

Laser safety features such as shielding, sensors, and protective accessories are essential and influence pricing.

Cost vs Value: Is a Handheld Laser Welder Worth It?

Although the initial laser welder cost may be higher than traditional welding equipment, many users find the long-term value compelling.

Reduced Labor Costs

Laser welding requires less post-weld finishing and rework, saving labor hours.

Higher Productivity

Faster welding speed allows more parts to be completed in less time.

Consistent Quality

Stable laser weld quality reduces scrap rates and customer complaints.

When evaluating small laser welding machine price, it is important to consider total cost of ownership rather than purchase price alone.

Materials Suitable for Laser Welding

Handheld laser welders are widely used for various metals, including:

- Stainless steel

- Carbon steel

- Galvanized steel

- Aluminum and aluminum alloys

- Certain copper alloys

Laser welding for stainless steel is especially popular due to clean seams and corrosion resistance. Aluminum laser welding requires precise parameter control but delivers excellent results with the right setup.

Typical Applications of Small Laser Welding Machines

Metal Fabrication and Workshops

Small laser welding machines are ideal for custom fabrication, thin sheet metal welding, and short production runs.

Repair and Maintenance

Laser weld technology is widely used for equipment repair, crack filling, and component refurbishment.

Automotive and Transportation

Applications include body panels, battery components, brackets, and exhaust systems.

Kitchen and Household Products

Laser welding provides smooth seams for sinks, cabinets, appliances, and stainless steel furniture.

Mold and Tool Repair

Precision laser welds allow accurate material addition without damaging surrounding areas.

Comparing Laser Welding to Traditional Welding Methods

Laser Welding vs TIG Welding

Laser welding offers faster speed, less distortion, and easier operation. TIG welding requires higher skill and generates more heat input.

Laser Welding vs MIG Welding

MIG welding is effective for thicker materials but produces spatter and requires cleanup. Laser welds are cleaner and more precise.

Laser Welding vs Resistance Welding

Laser welding provides greater design flexibility and material compatibility.

Choosing the Right Handheld Laser Welder

Step 1: Define Your Application

Identify material type, thickness range, and weld appearance requirements.

Step 2: Match Power to Material

Avoid overpowered systems if your work focuses on thin materials.

Step 3: Evaluate Portability Needs

Consider whether true portability is required or if a semi-fixed setup is sufficient.

Step 4: Prioritize Safety

Ensure the system includes proper laser safety features and clear operating guidelines.

Step 5: Consider After-Sales Support

Technical support, training, and spare parts availability are critical for long-term operation.

Laser Weld Quality: What Defines a Good Result?

A high-quality laser weld should demonstrate:

- Uniform penetration

- Smooth, consistent seam appearance

- Minimal porosity

- Strong mechanical strength

- Low thermal distortion

Proper focus position, stable travel speed, and correct shielding gas are essential for achieving consistent results.

Common Mistakes to Avoid When Buying a Small Laser Welding Machine

- Choosing based on price alone

- Ignoring safety requirements

- Selecting excessive power without application need

- Overlooking training and support

Avoiding these mistakes helps ensure a successful investment.

Future Trends in Small and Handheld Laser Welding

Laser welding technology continues to evolve toward:

- More compact system designs

- Lower entry-level pricing

- Smarter parameter control

- Wider adoption in small businesses

As costs decrease and performance improves, handheld laser welders are becoming a standard tool rather than a specialty solution.

Conclusion: Making the Right Investment in Laser Welding

Understanding small laser welding machine price, performance, and application requirements is essential for making an informed decision. A handheld laser welder offers unmatched flexibility, efficiency, and weld quality for modern metalworking needs.

For workshops, manufacturers, and repair professionals seeking higher productivity and cleaner laser welds, a small laser welding machine represents a forward-looking investment with strong long-term benefits.

By focusing on value, application fit, and total cost of ownership, businesses can fully leverage the advantages of laser weld technology.