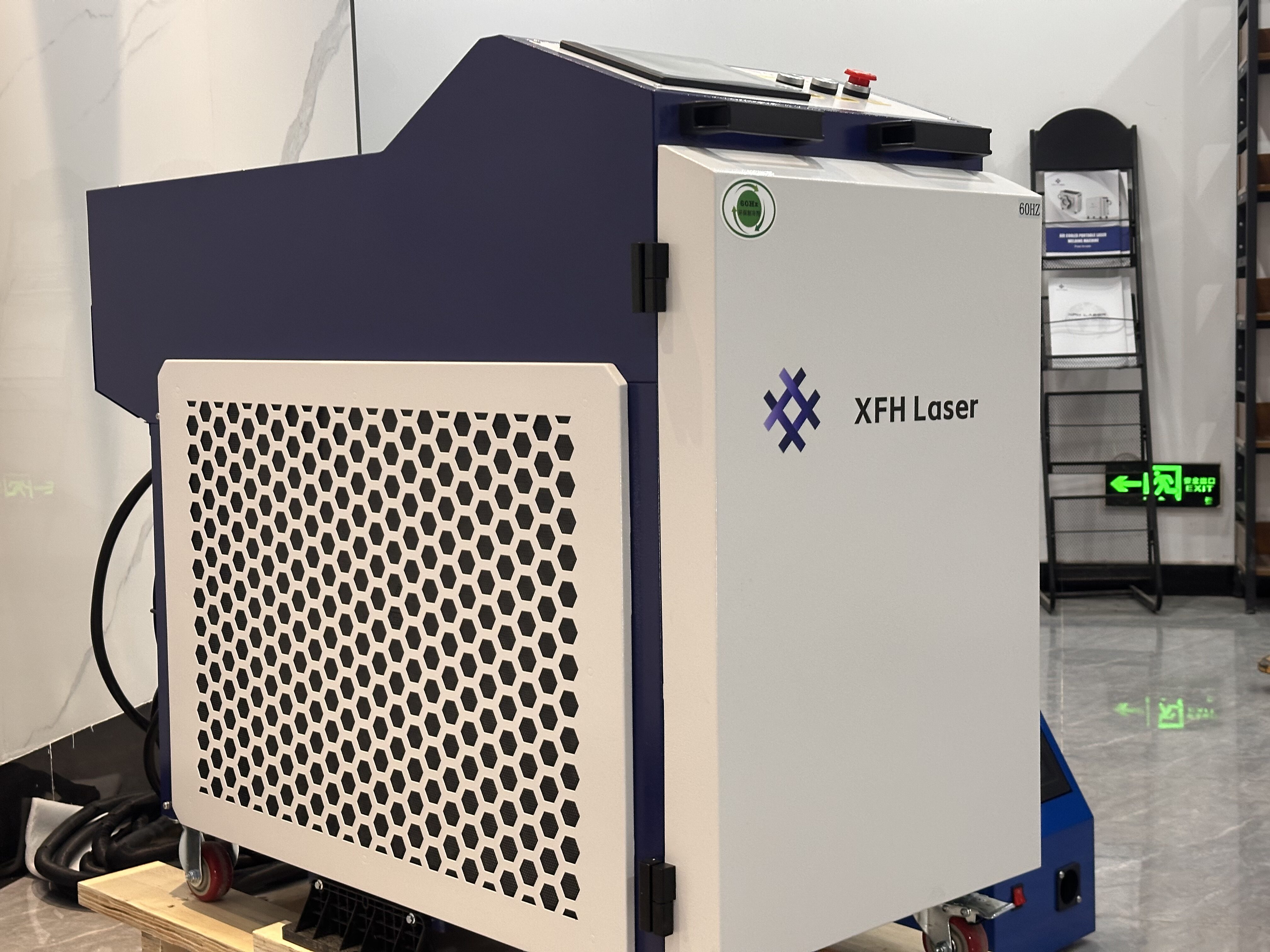

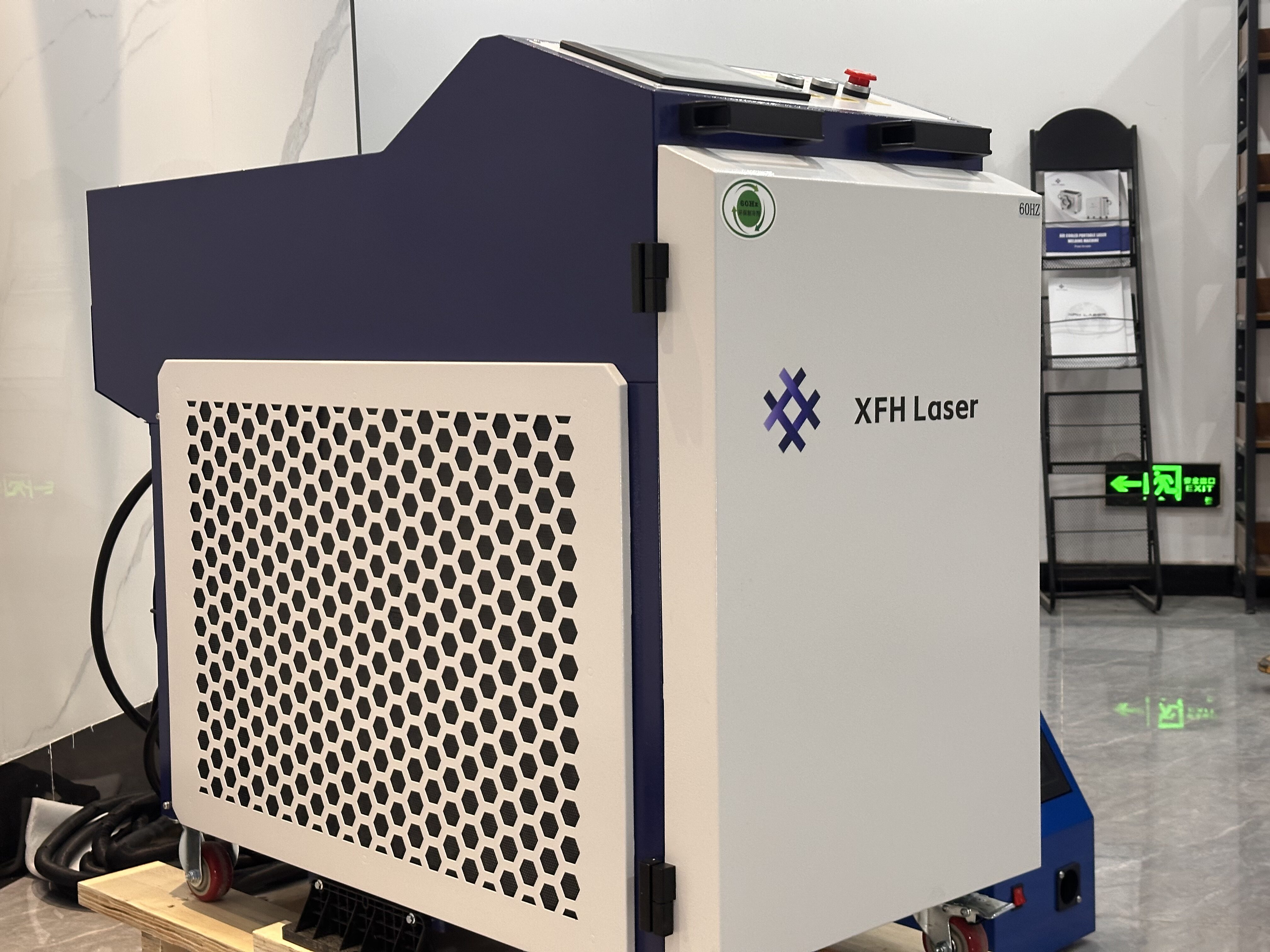

Laser Welder

Product Type: Laser Welder (4 in 1)

Laser Power: 1200W / 1500W / 2000W / 3000W

Laser Type: Fiber Laser

Cooling System: Water Cooling

Welding Thickness: 0.4 – 8 mm

Functions: Welding / Cutting / Cleaning / Seam Cleaning

Operation Mode: Handheld / Manual

Applicable Materials: Stainless Steel, Carbon Steel, Galvanized Steel, Aluminum

Category:Laser welder

Product Details

4 in 1 Laser Welder – One Machine, Four Industrial Functions

The 4 in 1 Laser Welder is a versatile, high-performance solution designed to meet the growing demands of modern metal fabrication workshops. By integrating laser welding, laser cutting, laser cleaning, and weld seam cleaning into a single compact system, this machine significantly reduces equipment investment while improving overall production efficiency.

Instead of purchasing and maintaining multiple standalone machines, manufacturers can rely on one powerful fiber laser welder to handle multiple processes with precision, speed, and consistency. This makes the 4 in 1 laser welder an ideal choice for small and medium factories, job shops, repair centers, and production lines seeking flexibility and long-term value.

Four Functions in One Laser Welder

1. Laser Welding

As a professional laser welder, the system delivers fast welding speed, deep penetration, and clean weld seams with minimal heat input. Compared to traditional TIG or MIG welding, laser welding offers higher efficiency, reduced deformation, and a much cleaner working environment. It is suitable for thin and medium-thickness metal sheets and supports both continuous and spot welding.

2. Laser Cutting

The integrated laser cutting function allows operators to cut thin metal sheets and small parts with high precision. This is especially useful for trimming components, preparing joints before welding, or handling small-batch customization without switching machines.

3. Laser Cleaning

Laser cleaning enables non-contact removal of rust, oxide layers, paint, oil, and surface contaminants. Unlike chemical or abrasive cleaning methods, laser cleaning does not damage the base material and requires no consumables, making it an eco-friendly and cost-effective solution.

4. Weld Seam Cleaning

After welding, the same laser welder can be used to clean weld seams, removing oxidation and discoloration to achieve a smooth, uniform finish. This is particularly valuable for stainless steel products where appearance and surface quality are critical.

Power Options for Different Applications

To suit a wide range of production needs, the 4 in 1 laser welder is available in multiple power configurations:

-

1200W

-

1500W

-

2000W

-

3000W

Depending on material type and laser power, the system supports welding thickness from 0.4 mm up to 8 mm. Lower power options are ideal for thin sheet metal and precision work, while higher power versions handle thicker materials and higher productivity requirements.

This flexible power selection allows users to choose the most cost-effective configuration without sacrificing performance.

Water-Cooled Industrial Design

The laser welder features a water-cooled industrial design engineered for long-term, continuous operation. The advanced water-cooling system ensures stable laser output, protects core components from overheating, and significantly extends service life.

Compared to air-cooled systems, water cooling provides better thermal control, making this laser welder suitable for high-duty industrial environments where reliability and consistency are essential. This design minimizes downtime and helps maintain stable performance even during extended production shifts.

Wide Material Compatibility

This fiber laser welder is compatible with a wide range of commonly used metals, including:

-

Stainless steel

-

Carbon steel

-

Aluminum

-

Galvanized steel

The laser welder produces smooth, strong welds on reflective and challenging materials, especially aluminum and galvanized steel, which are traditionally difficult to weld using conventional methods.

Handheld Operation for Maximum Flexibility

Equipped with a handheld laser welding head, the system allows operators to easily weld corners, curves, edges, and complex geometries. The ergonomic handheld design reduces operator fatigue and shortens training time, making it suitable for both experienced welders and new users.

Handheld operation also makes the laser welder ideal for on-site repairs, custom fabrication, and applications where fixed automation is not practical.

Cost-Effective and Space-Saving Solution

By combining four functions into one unit, the 4 in 1 laser welder:

-

Reduces equipment purchase cost

-

Saves workshop floor space

-

Lowers maintenance and operating expenses

-

Improves workflow efficiency

This all-in-one design helps manufacturers streamline operations while maintaining high-quality output across multiple processes.

Ideal Applications

The 4 in 1 laser welder is widely used in:

-

Stainless steel product manufacturing

-

Kitchen equipment and cabinets

-

Automotive parts and repair

-

Hardware and metal furniture

-

Custom metal workshops

Conclusion

The 4 in 1 Laser Welder is a powerful, flexible, and cost-efficient solution for modern metalworking. With laser welding, cutting, cleaning, and weld seam cleaning integrated into one system, it delivers exceptional versatility, high productivity, and long-term value. Whether for precision fabrication or industrial production, this laser welder is designed to meet diverse application needs with reliable performance.

Frequently Asked Questions

1. What is the most important factor when choosing a laser welder?

The two most important factors are material thickness and usage scenario. Material thickness determines the required laser power, while the application scenario determines whether you need a handheld, workstation, or automated laser welding system.

2. How does material thickness affect laser welder selection?

Laser power must match the thickness of the material to ensure proper penetration and weld strength.

- 0.5–3 mm: Low to medium power laser welders are suitable for thin sheet metal and precision parts.

- 3–6 mm: Medium power laser welders are ideal for general fabrication and industrial components.

- 6 mm and above: High-power laser welders are recommended for structural parts and heavy-duty welding.

Choosing insufficient power may cause weak welds, while excessive power can lead to burn-through on thin materials.

3. Can one laser welder handle different thicknesses?

Yes. Most modern laser welders offer adjustable power settings, allowing them to handle a range of thicknesses. However, the base laser power should always be selected according to the most common thickness used in daily production.

4. How does the welding scenario influence the choice?

- Handheld laser welding: Best for flexible jobs, repairs, small batches, and irregular workpieces.

- Workshop or production welding: Suitable for repeated welding of standard parts with consistent thickness.

- Industrial or heavy-duty welding: Requires higher power, stable cooling, and often automated systems for continuous operation.

5. Does material type matter in addition to thickness?

Yes. Materials like stainless steel and carbon steel weld easily, while aluminum and copper reflect more laser energy and usually require higher power or optimized parameters, even at the same thickness.

6. Is higher laser power always better?

No. Higher power increases penetration but also raises cost and the risk of overheating thin materials. The best choice is a laser welder that matches your actual thickness range and application needs, not simply the highest wattage available.

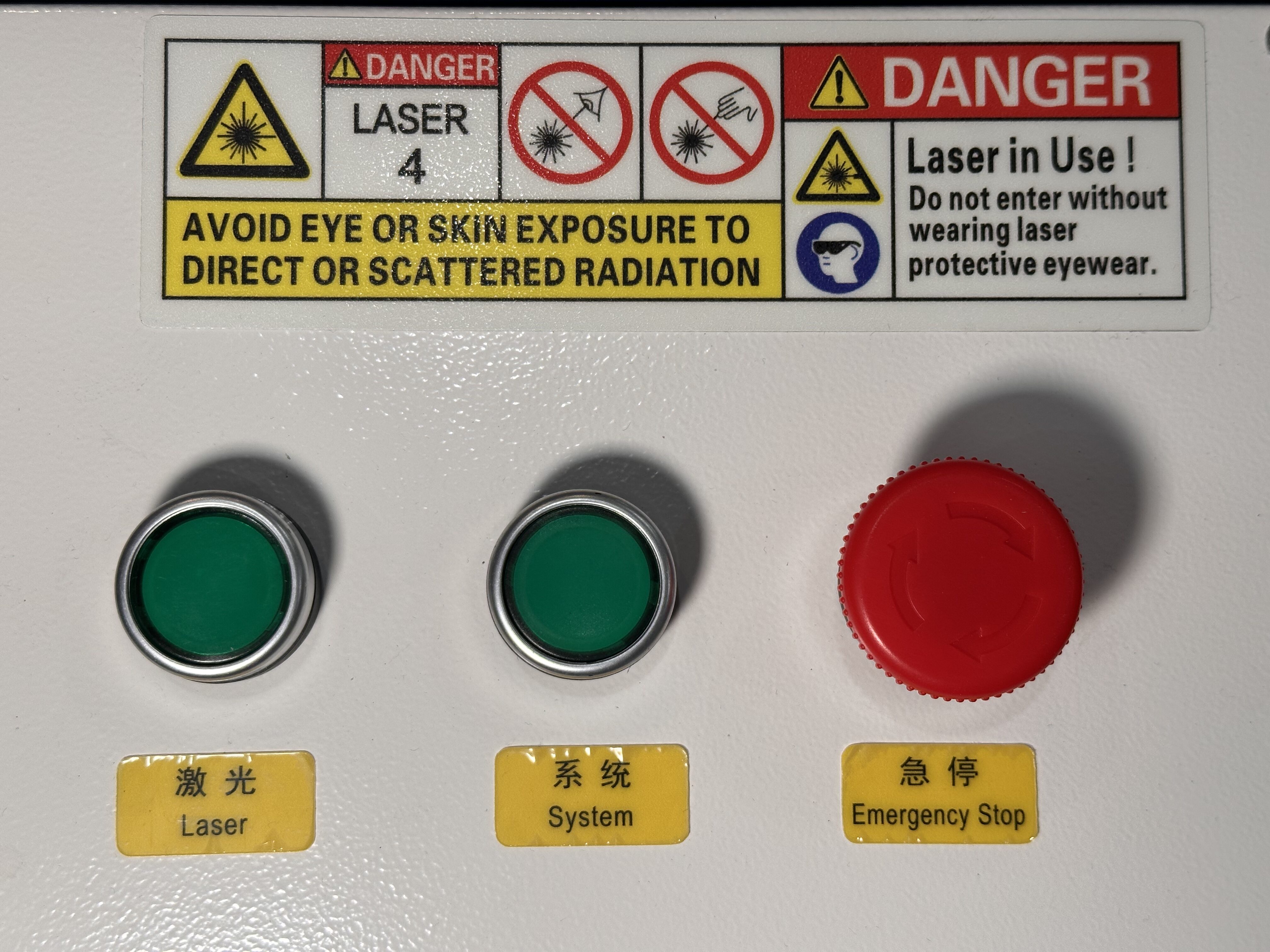

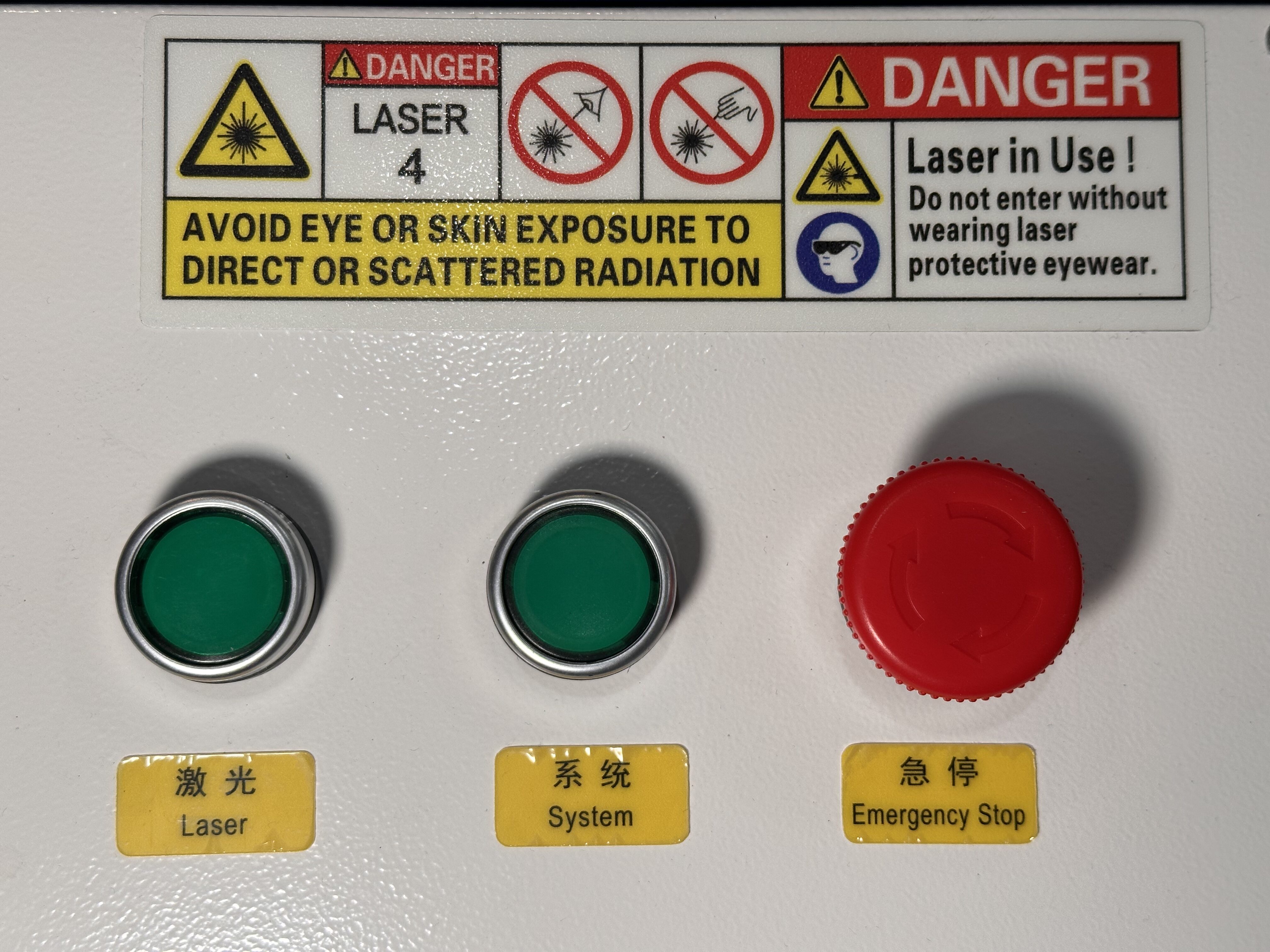

7. What other features should I consider?

In addition to laser power, consider:

- Cooling system stability

- Welding head control and ergonomics

- Safety features and ease of operation

- Suitability for continuous or intermittent use

These factors directly affect long-term welding quality and productivity.

Summary

To choose the right laser welder, start with material thickness, then match it with your welding scenario. A properly selected laser welder delivers stable penetration, clean welds, and higher efficiency without unnecessary cost.

1. What is the first thing to consider when choosing a laser cleaning machine?

Start by identifying your cleaning needs: the type of material (metal, plastic, rubber), the kind of contaminants (rust, paint, oil), and the size of surfaces you will clean most often. Matching machine specs to these requirements is essential for effective cleaning.

2. How does laser power affect the choice?

Laser power determines how fast and effectively contaminants are removed:

- Low power (20–200W): Suitable for delicate surfaces, light rust, thin paint, or precision tasks.

- Medium power (200–500W): Ideal for general cleaning of rust, grease, and paint on moderate-sized parts.

- High power (500W+): Best for heavy-duty cleaning on thick coatings and large surfaces in industrial environments.

Choose the lowest power that safely handles your hardest cleaning task to avoid surface damage and excessive cost.

3. Should I choose handheld or stationary?

Handheld machines are great for flexible on-site cleaning, repairs, and variable workpieces. Stationary units or automated systems suit high-volume production, assembly lines, or fixed cleaning stations.

4. Is wavelength important?

Yes. The laser wavelength affects how well energy is absorbed by the material:

-

Fiber lasers (~1064 nm): Common for most metal cleaning.

-

CO₂ lasers (~10.6 µm): Often better for non-metal materials like plastics or wood.

Matching wavelength to material improves cleaning efficiency and reduces heat damage.

5. What about pulse type and frequency?

Laser cleaners can operate in pulsed or continuous modes:

-

Pulsed lasers: Deliver bursts of energy, reducing heat impact — ideal for precision cleaning and sensitive surfaces.

-

Continuous wave lasers: Provide steady output, useful for bulk contaminant removal where thermal impact is less critical.

Pulse frequency and duration influence how aggressively contaminants are removed without harming the substrate.

6. How does production volume influence my choice?

-

Small batches or occasional use: Compact or portable systems work best.

-

Continuous high throughput: Fixed or automated laser cleaning machines with robust cooling and duty cycles improve productivity.

Always consider how much cleaning your operation requires over time.

7. What safety and support features should I look for?

Ensure the machine has proper safety measures (interlocks, shielding), cooling systems to manage heat, and quality support from the supplier for training, maintenance, and repairs. Good safety design and after-sales service reduce risk and downtime.

8. Do I need to consider long-term costs?

Yes — look beyond the purchase price. Factor in operational costs like energy consumption, maintenance, consumables (filters, optics), and downtime costs. A machine that is inexpensive upfront but costly to maintain can reduce overall value.

9. Is testing important before buying?

Absolutely. Testing with your materials and contaminant types helps verify cleaning speed, power sufficiency, and surface impact. This practical step prevents mismatches between specifications and real-world performance.

10. What’s the best way to balance performance and cost?

Choose a machine that meets your heaviest cleaning need without over-specifying. For most general industrial tasks, a mid-range power laser cleaner (200–500W) balances cost, flexibility, and capability. For specialized tasks, adjust power, configuration, and automation accordingly.