Handheld Welders: A Complete Guide for DIY and Professional Welding

News 2022-06-14

In modern metalworking, handheld welders have become essential tools for both professionals and DIY enthusiasts. Their portability, flexibility, and ease of use make them ideal for a wide range of applications—from automotive repairs to custom metal fabrication and small-scale workshop projects. Unlike traditional stationary welding machines, handheld welders provide the ability to weld on the go, making it easier to work in tight spaces, remote locations, or outdoor environments.

Whether you are a seasoned welder or a hobbyist looking to expand your skills, understanding the different types of handheld welders, how they work, and how to use them safely is key to achieving professional results. This guide will walk you through everything you need to know about handheld welders, including types, applications, safety tips, and project ideas.

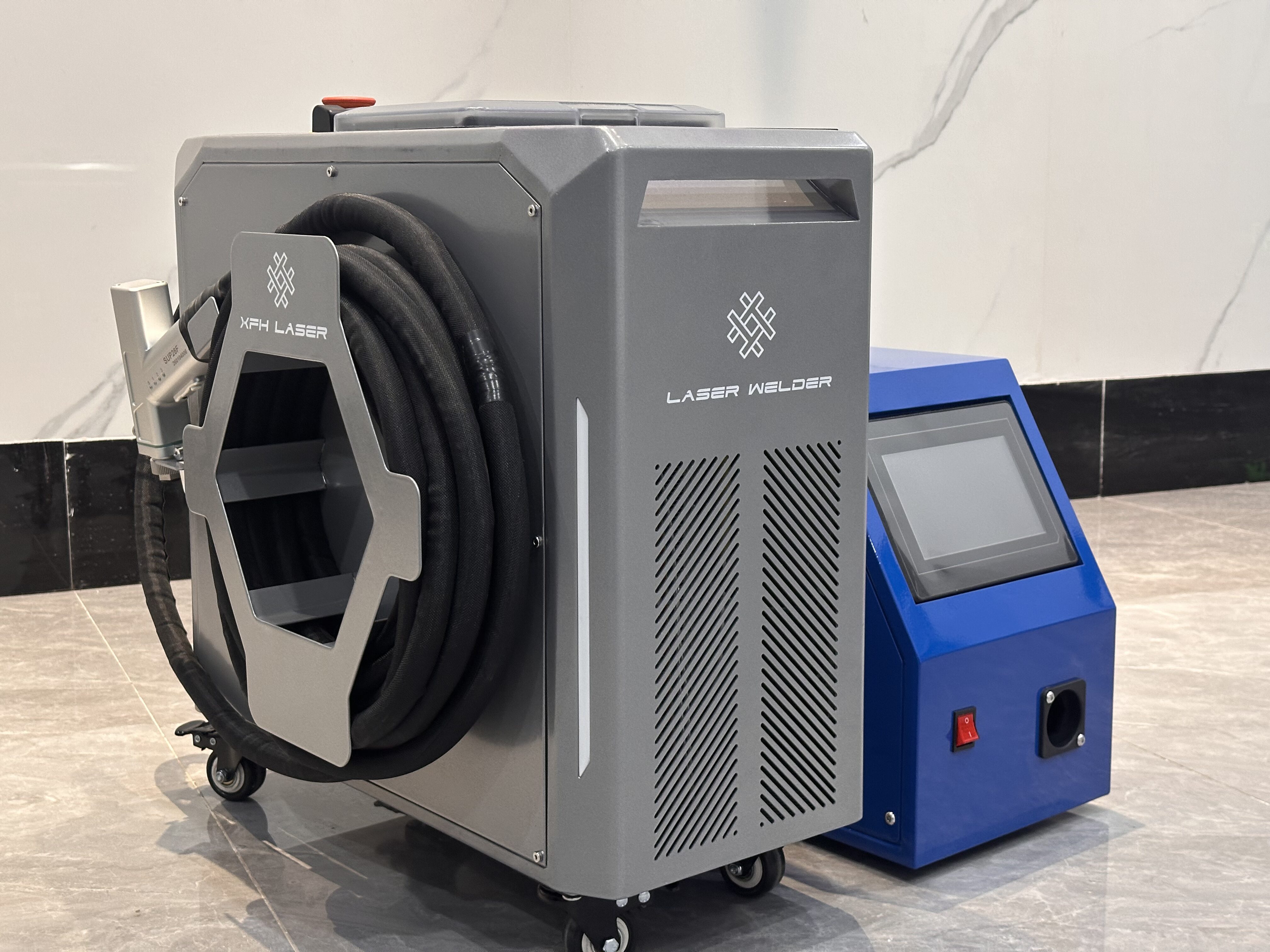

What Is a Handheld Welder and How It Works

A handheld welder is a portable welding machine designed to join metal parts using heat generated from an electric arc or laser. Unlike larger stationary welders, handheld devices are compact, lightweight, and easy to transport. These machines allow users to weld in locations that would be difficult or impossible with a traditional welding setup.

The principle of operation depends on the welding type:

- Arc Welding (SMAW): Uses a consumable electrode to generate heat and fuse metals. Ideal for thicker metals and outdoor environments.

- MIG Welding (GMAW): Uses a continuously fed wire and shielding gas to produce a clean weld. Great for thin metals and fast production.

- TIG Welding (GTAW): Provides precise control with high-quality, clean welds. Best suited for metals requiring exact tolerances like aluminum and stainless steel.

- Battery-Powered or Inverter Handheld Welders: Modern options that allow cordless operation or improved energy efficiency for light-duty and mobile welding tasks.

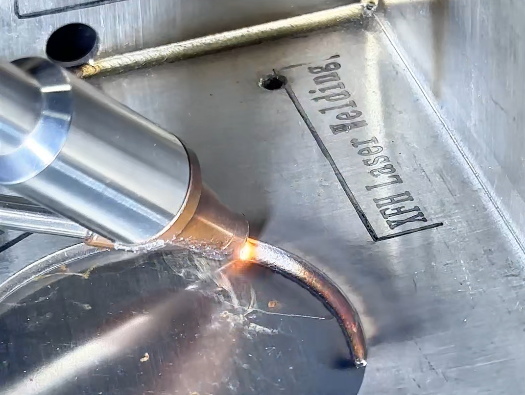

A handheld welder operates by generating intense heat at the welding point, melting the metal and fusing it together. In MIG and TIG welding, additional filler material may be used to strengthen the weld. The precision of handheld welders combined with their portability makes them versatile for a wide range of tasks.

Types of Handheld Welders

Choosing the right handheld welder depends on your materials, application, and skill level. Here are the most common types:

1. Stick Welding (SMAW)

Stick welding is simple, reliable, and effective, especially outdoors or in less controlled environments. It uses a consumable electrode that melts to form the weld.

Advantages:

- Simple setup

- Can weld thick metals

- Works well in outdoor conditions

Disadvantages:

- Requires more post-weld cleaning

- Produces more splatter

- Heavier equipment

2. MIG (GMAW)

MIG welding is favored for its speed, clean welds, and ease of use. It uses a wire feed and shielding gas to create smooth welds.

Advantages:

- High welding speed

- Minimal finishing required

- Good for thin metals and sheet fabrication

Disadvantages:

- Requires shielding gas

- Less effective in windy or outdoor conditions without proper protection

3. TIG (GTAW)

TIG welding allows precise, clean welds with high-quality finish. It is ideal for critical projects that require strength and aesthetics.

Advantages:

- Excellent precision and weld quality

- Minimal spatter and clean welds

- Ideal for aluminum, stainless steel, and delicate metals

Disadvantages:

- Higher skill requirement

- Slower than MIG or stick welding

- More expensive

4. Battery-Powered & Inverter

These modern welders offer portability without the need for a constant power supply. They are suitable for small projects, fieldwork, and emergency repairs.

Advantages:

- Compact and lightweight

- Cordless operation

- Energy efficient

Disadvantages:

- Limited power for thick metals

- Shorter duty cycles

Applications of Handheld Welders

Handheld welders are versatile and used across many sectors:

Metal Fabrication

Perfect for creating custom metal parts, brackets, and machinery repairs. MIG and TIG handheld welders excel in workshops and manufacturing facilities.

Automotive Repairs

Ideal for fixing car frames, brackets, exhaust systems, and light vehicle restoration.

DIY Projects & Home Improvement

From building furniture to repairing fences, handheld welders allow hobbyists to complete metal projects at home.

Outdoor & Emergency Repairs

Portable welders are excellent for fieldwork, construction sites, and quick repair jobs where access to power may be limited.

Advantages of Using a Handheld Welder

The primary benefits of handheld welding machines include:

- Portability: Easy to carry to different job sites

- Flexibility: Can weld in tight spaces and awkward angles

- Time Efficiency: Quick setup and minimal preparation

- Multi-Purpose: Can be used for repairs, fabrication, or DIY projects

- Cost-Effective: Eliminates the need for large stationary equipment for small tasks

Disadvantages of Handheld Welders

Despite their convenience, handheld welders have some limitations:

- Limited Power: May not handle extremely thick materials

- Skill Dependent: Quality welds require practice

- Battery Limitations: Cordless versions may have short runtime

- Durability: Portable units may be less robust than industrial stationary welders

Choosing the Right Handheld Welder

When selecting a handheld welder, consider the following:

1. Material and Thickness

- MIG/TIG for thin metals

- Stick welding for thicker materials

2. Power Source

- Corded machines for continuous work

- Battery-powered for portability

3. Skill Level

- MIG is beginner-friendly

- TIG requires advanced skill

4. Budget

- Balance upfront cost with long-term durability and performance

5. Safety Features

- Thermal protection

- Overcurrent protection

- Ergonomic design

Safety Tips

Safety is critical when using handheld welders:

1. Personal Protective Equipment (PPE)

- Welding helmet with proper shading

- Flame-resistant gloves and clothing

- Safety goggles for eye protection

2. Ventilation

- Weld in a well-ventilated area to avoid inhaling fumes

- Use extraction fans or hoods if indoors

3. Fire Safety

- Keep flammable materials away

- Have a fire extinguisher nearby

4. Proper Setup

- Secure workpieces

- Inspect cables and connections for wear or damage

5. Beginner Tips

- Start with scrap metal for practice

- Learn correct arc length and travel speed

Projects to Try

1. DIY Metal Art

- Wall sculptures, garden ornaments, and decorative frames

2. Home & Garden Repairs

- Fence posts, gates, and metal furniture

3. Automotive Projects

- Exhaust repairs, brackets, and chassis reinforcement

4. Custom Builds

- Tools, racks, or workshop fixtures

Troubleshooting Common Handheld Welder Issues

- Weak or uneven welds: Check electrode, voltage, and travel speed

- Arc instability: Inspect grounding, wire feed, and electrode

- Overheating: Allow cooling, check duty cycle limits

- Material-specific issues: Adjust settings for aluminum, stainless steel, or thin metals

Conclusion

Handheld welders are a game-changer for both professionals and DIY enthusiasts. Their portability, flexibility, and multi-purpose use make them ideal for a wide range of applications—from workshop fabrication to field repairs. Understanding the types, applications, and safety considerations of handheld welding machines ensures better results, increased efficiency, and safer operation.

Whether you are just starting your welding journey or upgrading your tools, a high-quality handheld welder can expand your capabilities and enable you to complete projects that were once challenging or impossible. Explore the right portable welding solution to enhance your workshop or project workflow today.