Affordable Laser Welders: Prices, Types, and Buying Guide (2026)

News 2026-02-06

Introduction

In recent years, laser welding machines have become increasingly popular across industries, from small metal workshops to high-end manufacturing facilities. Their precision, efficiency, and ability to handle delicate and complex metalwork have made them a staple in modern fabrication and repair processes. With the growing demand, many newcomers to the field are curious about the laser welder price, especially when encountering budget-friendly models online.

While affordable devices may seem tempting, buyers should be aware that not all advertised “laser welders” deliver genuine laser welding performance. This guide will break down the true laser welder price ranges, highlight different types of machines, and provide practical tips to make informed purchase decisions in 2026.

1. What is a Laser Welder?

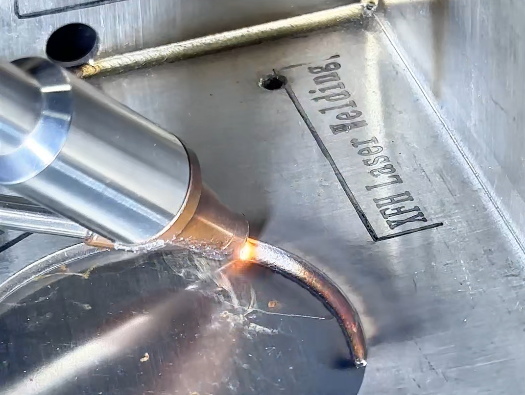

A laser welder is a machine that uses a focused laser beam to join metal parts together. Unlike traditional welding methods such as MIG or TIG, laser welding provides:

- Minimal heat-affected zones

- Cleaner weld seams

- High precision for thin metals and delicate workpieces

- Faster welding speeds and reduced labor costs

Laser welders are widely used in industries such as automotive, electronics, jewelry, aerospace, and small-scale repair shops. They are particularly useful for achieving a professional finish on metals that are difficult to weld using conventional methods.

2. Types of Laser Welding Machines

Understanding the different types of laser welding machines is crucial for evaluating their prices and selecting the right model for your needs.

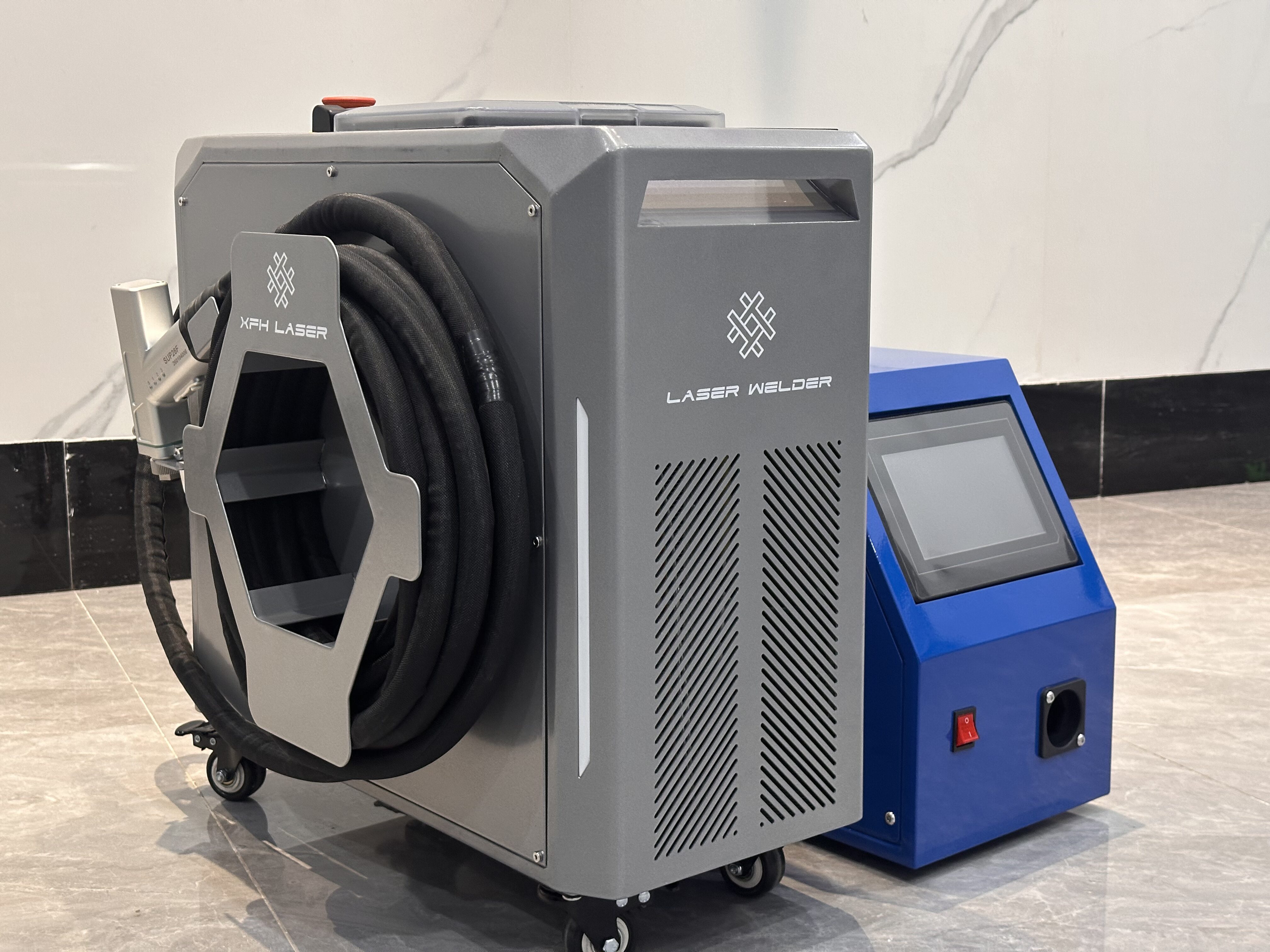

2.1 Handheld Laser Welders

Handheld laser welders are portable, user-friendly devices suitable for small workshops or repair operations. They are ideal for:

- Jewelry repair

- Car body maintenance

- Thin sheet metal welding

These machines often include simple digital controls and may offer integrated functions such as laser cleaning or cutting in some multi-purpose models. The main advantage of handheld units is flexibility and ease of use.

2.2 Desktop/Fixed Laser Welders

Desktop laser welders are stationary systems designed for small-scale production or precision metalworking. They provide:

- Higher stability

- Consistent weld quality

- Longer operational life

These systems are often used in industrial applications where precision and repeatability are critical.

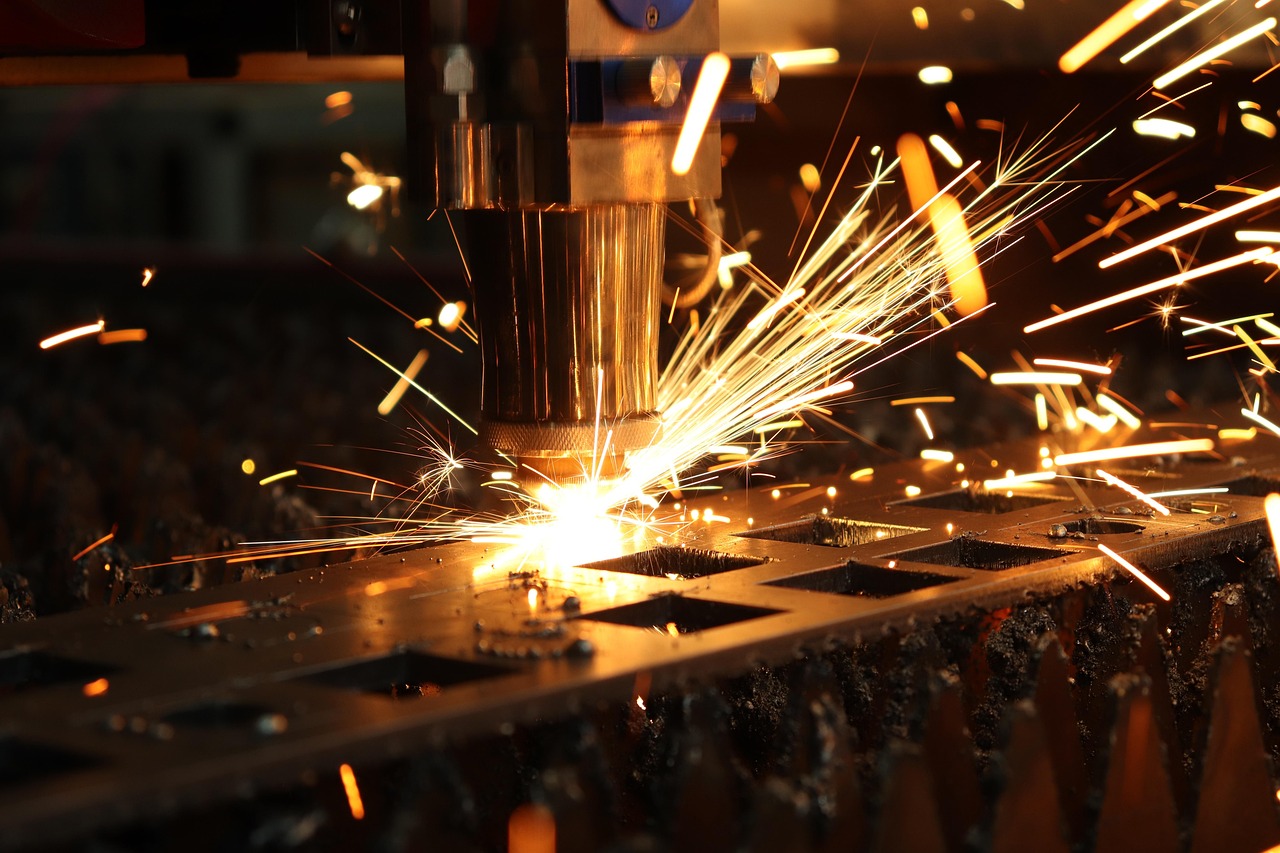

2.3 Industrial Robotic Laser Welders

For large-scale manufacturing, robotic laser welding systems provide automated, high-volume welding capabilities. Benefits include:

- Increased productivity

- Minimal operator intervention

- Seamless integration into automated production lines

However, these systems come at a significantly higher cost compared to handheld or desktop welders.

2.4 Multi-functional “3-in-1” Laser Machines

Some modern units combine welding, cutting, and cleaning functions into one device. These machines are especially useful for repair shops that need versatile solutions without investing in multiple machines.

3. Laser Welder Price in 2026

The laser welder price varies greatly depending on power, type, and functionality. Buyers should understand the market to avoid low-quality or misleading products.

3.1 Handheld Laser Welder Prices

| Device Category | Power (Watts) | Approx. Price (USD) | Typical Use Case |

|---|---|---|---|

| Entry-level portable | 500–1000 | $2,000–$4,000 | Small repairs, thin metal welding |

| Mid-range handheld | 1000–2000 | $3,000–$5,000 | Small production, repair shops |

| High-power/multi-purpose | 1500+ | $4,000–$8,000+ | Medium-to-large manufacturing, 3-in-1 functions |

3.2 Desktop and Fixed Laser Welder Prices

- Small desktop units: $8,000–$20,000

- Large industrial fixed systems: $8,000–$30,000+ depending on configuration

Factors affecting price include laser power, cooling system (air vs. water-cooled), software control, and additional functionality.

4. Common Traps in Low-Cost Laser Welders

Many online platforms advertise ultra-cheap laser welders, but buyers should be cautious. Common issues include:

- Misleading Marketing: Some products labeled as “laser welders” are low-quality devices or imitation machines with little to no real laser capability.

- Safety Hazards: Substandard devices can expose operators to unsafe laser emissions or electrical faults.

- Poor Performance: Low-power, cheap welders often fail to weld metals effectively or produce inconsistent results.

Reddit and other forums have documented cases of users purchasing “$100 laser welders” that turned out to be useless for actual welding purposes.

5. Key Factors Affecting Laser Welder Price

5.1 Laser Power

Higher power generally allows for welding thicker metals and faster processing. Lower-power machines are limited to thin sheets or delicate tasks.

5.2 Cooling System

- Air-cooled welders are simpler and cheaper but may overheat under continuous use.

- Water-cooled welders provide stable operation for extended periods, increasing cost.

5.3 Additional Features

- Integrated cutting or cleaning functionality increases machine versatility.

- Advanced control systems (digital panels, adjustable modes) can justify higher prices.

5.4 Brand, Support, and Warranty

- Established brands often charge more for reliability, support, and access to spare parts.

- Warranty coverage and after-sales support can significantly impact total cost of ownership.

5.5 Supply Chain and Regional Factors

- Imported machines may have higher costs due to shipping, taxes, and customs.

- Direct factory purchases often offer better laser welder price deals than distributors.

6. Total Cost of Ownership

When calculating the cost of a handheld laser welder or industrial unit, consider:

- Initial purchase price

- Operating costs: electricity, cooling, maintenance, consumables

- Training costs: ensuring operators can safely and efficiently use the equipment

- Machine lifespan: factoring in depreciation and replacement cycles

A low upfront price may result in higher long-term costs if the machine lacks durability or requires frequent repairs.

7. Tips for Buying a Laser Welder

7.1 Determine Your Needs

- Light repair work vs. small-scale production vs. industrial automation

- Required precision, material types, and workflow

7.2 Check Real Technical Specifications

- Laser type (fiber, diode, pulse)

- Power output and beam quality

- Cooling system and duty cycle

7.3 Look for Verified User Reviews

- Community feedback and case studies reveal real-world performance

- Avoid relying solely on marketing images or claims

7.4 Avoid Unrealistic Low Prices

- If a machine is priced far below typical laser welder price ranges, investigate carefully

- Ensure the seller provides clear specifications, warranty, and support

8. Conclusion

Investing in a laser welding machine can enhance precision, efficiency, and product quality. While it may be tempting to opt for the cheapest option, understanding the true laser welder price, types of machines, and potential pitfalls is crucial for a smart purchase.

Whether you need a handheld laser welder for small repair jobs or a full-scale industrial system, choosing the right equipment ensures safer operation, higher productivity, and better long-term value.

By following the tips outlined above and carefully evaluating the machine specifications, you can confidently select the best laser welder for your budget and application.