Laser Cleaning Machine: The Complete Industrial Guide

News 2022-06-14

As industries worldwide continue to pursue higher efficiency, cleaner production, and lower operating costs, traditional surface cleaning methods are increasingly struggling to meet modern manufacturing demands. Sandblasting, chemical cleaning, and manual grinding often involve high labor costs, environmental concerns, and inconsistent results.

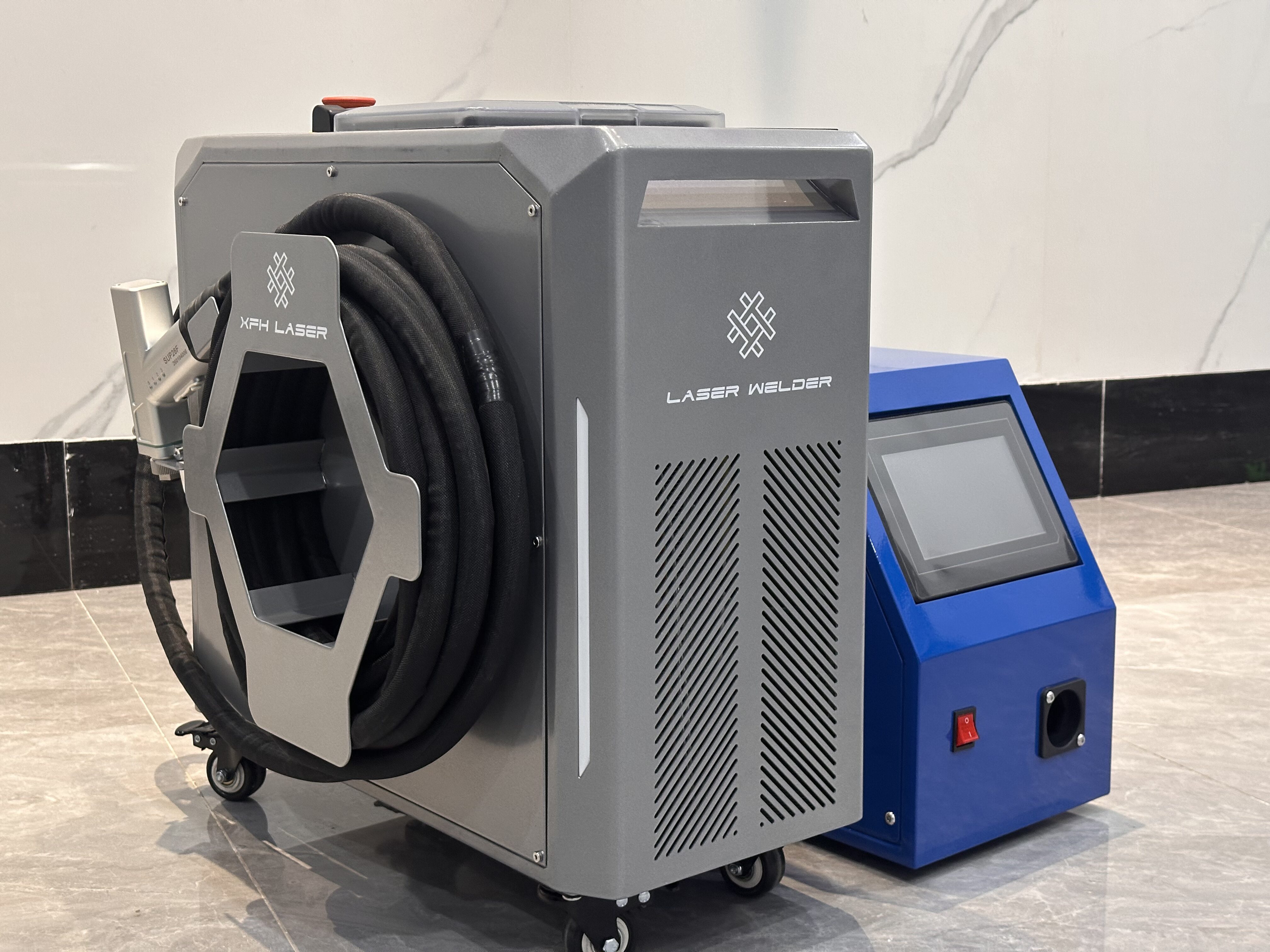

In this context, the laser cleaning machine has emerged as a powerful and innovative solution for industrial surface treatment. With its non-contact operation, precise control, and environmentally friendly process, laser cleaning technology is rapidly transforming industries such as metal fabrication, automotive repair, aerospace, mold maintenance, and heavy equipment manufacturing.

This comprehensive guide explains how laser cleaning machines work, their advantages, applications, different system types, limitations, and how to choose the right laser cleaning machine for your business.

How Does a Laser Cleaning Machine Work?

Understanding the working principle of a laser cleaning machine helps users maximize performance and choose the right system.

When the laser beam strikes the surface:

- The contaminant layer absorbs the laser energy more efficiently than the base material

- Rapid heating causes the contamination to expand, vaporize, or break its adhesion

- The unwanted material is removed, often assisted by micro-shockwaves

- The base material remains largely unaffected due to controlled energy density

Key adjustable parameters include laser power, pulse duration, frequency, scanning speed, and spot size. By precisely tuning these parameters, a pulse laser cleaning machine can remove delicate coatings without harming sensitive surfaces, while high-power fiber laser cleaning machines can efficiently remove thick rust or paint layers.

Key Advantages

Environmentally Friendly Cleaning

One of the biggest advantages of a laser cleaning machine is its eco-friendly nature. The process does not require chemicals, solvents, or abrasive media. As a result, there is no secondary pollution, wastewater, or chemical residue disposal.

This makes laser cleaning ideal for companies aiming to meet stricter environmental regulations and sustainability goals.

Non-Contact and Damage-Free Process

Traditional methods such as sandblasting or mechanical grinding may damage the surface profile or weaken the base material. A laser cleaning machine operates without physical contact, significantly reducing the risk of deformation, scratches, or micro-cracks.

This is especially important in applications requiring high precision, such as mold cleaning, aerospace components, and precision metal parts.

High Precision and Selective Cleaning

Laser cleaning allows selective removal of surface layers. Users can clean specific areas without affecting surrounding materials, which is difficult to achieve with conventional methods.

Pulse laser cleaning machines are particularly suitable for applications requiring micron-level control, such as oxide removal before welding or cleaning sensitive electronic components.

High Efficiency and Productivity

Compared with manual cleaning or chemical soaking, laser cleaning machines offer significantly faster processing speeds. Automated scanning systems and programmable parameters allow for consistent, repeatable results, reducing downtime and increasing production efficiency.

For industrial maintenance, a handheld laser cleaning machine enables operators to clean equipment directly on-site, eliminating disassembly time.

Lower Long-Term Operating Costs

Although the initial investment in a laser cleaning machine may be higher, long-term costs are often lower. There are no consumables such as sand, chemicals, or solvents, and maintenance requirements are minimal.

Over time, businesses benefit from reduced labor costs, lower waste disposal fees, and increased production uptime.

Types

Fiber Laser Cleaning Machine

A fiber laser cleaning machine uses a fiber laser source known for stability, long service life, and high energy efficiency. These systems are widely used in industrial environments for continuous operation and heavy-duty cleaning tasks.

They are suitable for rust removal, paint stripping, weld preparation, and large-scale surface treatment.

Pulse Laser Cleaning Machine

A pulse laser cleaning machine delivers energy in short, high-intensity pulses. This allows precise control of heat input, making it ideal for delicate applications where surface damage must be avoided.

Pulse systems are commonly used for mold cleaning, oxide removal, heritage restoration, and precision manufacturing.

Handheld Laser Cleaning Machine

A handheld laser cleaning machine offers portability and flexibility. Operators can easily clean large equipment, complex geometries, or hard-to-reach areas.

These systems are widely used in shipyards, construction sites, automotive repair shops, and industrial maintenance operations where mobility is essential.

Industrial Applications

Metal Fabrication and Welding Preparation

Laser cleaning machines are commonly used to remove rust, oil, and oxide layers before welding. Clean surfaces improve weld penetration, strength, and consistency, making laser cleaning an ideal pre-treatment process.

Automotive and Transportation Industry

In automotive manufacturing and repair, laser cleaning is used for paint removal, weld seam preparation, brake component cleaning, and restoration work without damaging underlying metal.

Aerospace and High-Precision Manufacturing

Aerospace components demand strict quality standards. Laser cleaning machines enable controlled removal of coatings and contaminants without affecting critical dimensions or material properties.

Mold and Tool Maintenance

Mold cleaning is one of the most popular applications for pulse laser cleaning machines. The non-contact process removes residues efficiently while extending mold life and reducing downtime.

Industrial Maintenance and Rust Removal

For heavy equipment, pipelines, and structural steel, laser cleaning machines provide fast and effective rust removal without abrasive wear, making them ideal for maintenance and refurbishment.

Laser Cleaning vs. Traditional Cleaning Methods

Compared to sandblasting, chemical cleaning, and mechanical grinding, laser cleaning offers clear advantages:

- No abrasive media or chemicals

- Minimal waste and environmental impact

- Higher precision and repeatability

- Reduced labor and maintenance costs

- Safer working conditions

While traditional methods still exist for certain low-cost tasks, laser cleaning machines are rapidly becoming the preferred solution for high-quality industrial applications.

Limitations and Considerations

Despite its many advantages, laser cleaning technology has some limitations:

- Higher initial equipment cost

- Requires proper safety measures, such as laser protective eyewear

- Less effective on highly reflective or transparent materials

- Operator training is recommended for optimal results

Understanding these factors helps users select the right system and maximize return on investment.

How to Choose the Right Laser Cleaning Machine

When selecting a laser cleaning machine, consider the following factors:

Material Type and Contaminant Thickness

Different materials and contamination layers require different laser power levels and pulse settings.

Cleaning Area and Speed Requirements

Large-scale industrial applications may require high-power fiber laser cleaning machines, while precision tasks benefit from pulse systems.

Portability Needs

If on-site cleaning is required, a handheld laser cleaning machine may be the best option.

Safety and Compliance

Ensure the system meets local safety regulations and includes proper protective measures.

The Future of Laser Cleaning Technology

As industries continue to adopt cleaner and smarter manufacturing practices, laser cleaning machines are expected to play an increasingly important role. Advances in laser sources, automation, and intelligent control systems will further improve efficiency, precision, and accessibility.

Laser cleaning is no longer a niche technology—it is becoming a standard solution for modern industrial surface treatment.

Conclusion

A laser cleaning machine offers an advanced, efficient, and environmentally friendly alternative to traditional cleaning methods. Whether used for rust removal, surface preparation, mold maintenance, or industrial refurbishment, laser cleaning technology delivers superior results with lower long-term costs.

By understanding the technology, applications, and selection criteria, businesses can make informed decisions and fully leverage the benefits of laser cleaning machines in modern manufacturing.