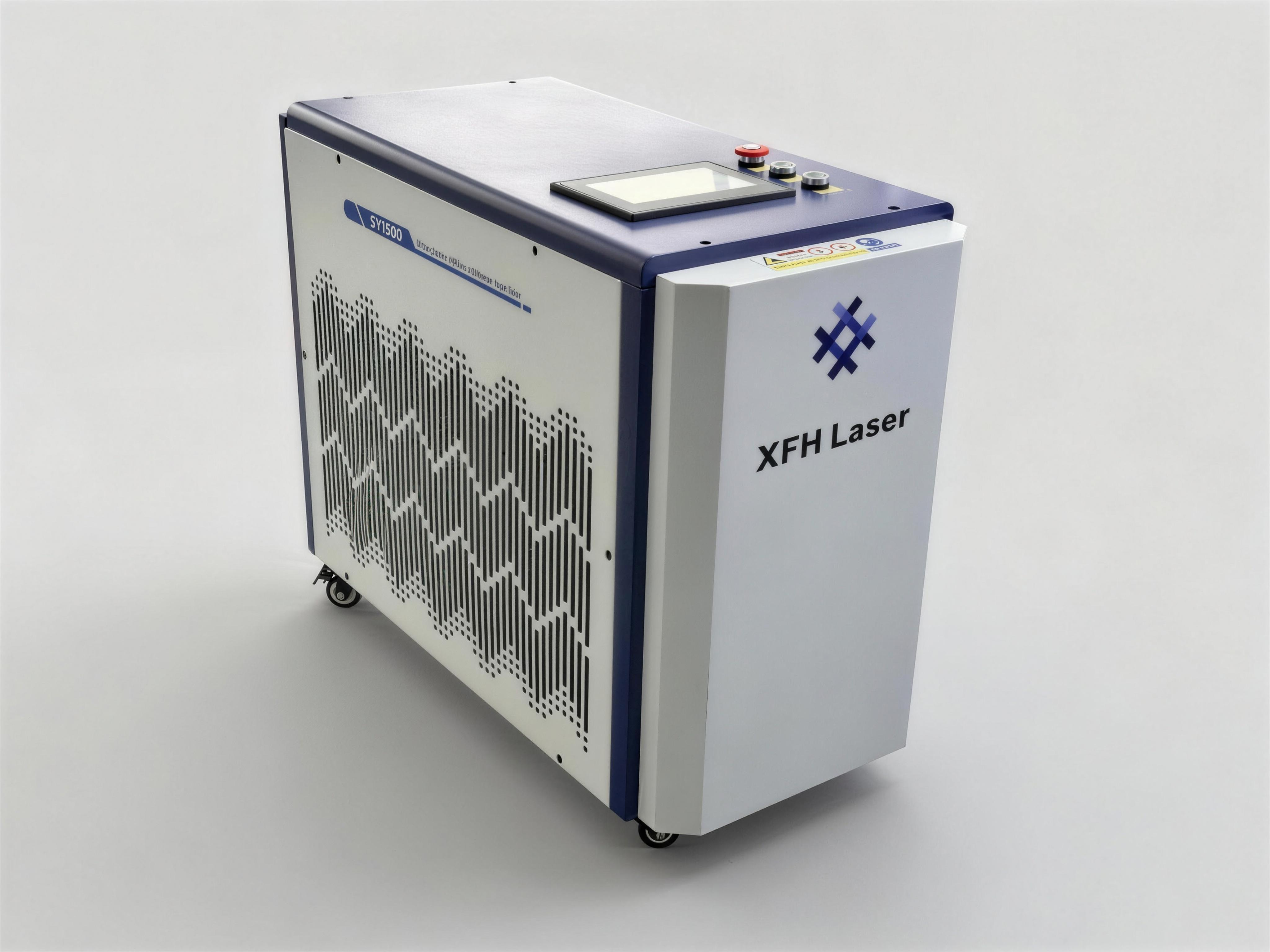

Laser cleaning machine

-

Machine Type: High Power Laser Cleaning Machine

-

Laser Source: High-power Fiber Laser

-

Power Options: 1000W / 1500W / 2000W / 3000W

-

Cleaning Mode: Continuous Wave (CW) / Pulsed (optional)

-

Cleaning Width: 100–500 mm (adjustable)

-

Cleaning Speed: Up to 30 m/min (depending on surface condition)

-

Cooling Method: Industrial Water Cooling

-

Power Supply: AC 380V, 50–60Hz

-

Operation Mode: Handheld / Robotic / Automatic system compatible

-

Control System: Touch screen + intelligent control

-

Laser Wavelength: 1064 nm

-

Safety Class: Class 4 (with safety protection system)

-

Applications: Heavy rust removal, thick paint stripping, oxide layer cleaning, shipbuilding, steel structures, molds, and industrial surface treatment

Category:Laser cleaning machine

Product Details

Laser Cleaning Machine for Efficient and Eco-Friendly Surface Treatment

The laser cleaning machine is an advanced surface cleaning solution designed to provide efficient, non-contact, and environmentally friendly cleaning for a wide range of industrial applications. By using high-energy laser pulses to remove surface contaminants, this system effectively eliminates rust, paint, oil, coatings, and residues without damaging the base material. With stable performance, low maintenance requirements, and high cleaning efficiency, the laser cleaning machine has become an essential tool in modern industrial surface preparation and maintenance.

As industries increasingly seek cleaner and more sustainable manufacturing processes, laser cleaning offers a powerful alternative to traditional methods such as sandblasting, chemical cleaning, or mechanical grinding. It delivers precise cleaning results while reducing environmental impact and operational costs.

Non-Contact Cleaning Without Material Damage

One of the most significant advantages of a laser cleaning machine is its non-contact cleaning process. The laser beam interacts only with the unwanted surface layer, vaporizing or detaching contaminants while leaving the underlying substrate intact. This precise energy control prevents surface damage, deformation, or micro-cracking, even on sensitive or high-value components.

This feature makes laser cleaning particularly suitable for applications where surface integrity and dimensional accuracy are critical, such as mold cleaning, precision metal parts, and pre-welding surface preparation.

High Cleaning Efficiency and Stable Performance

The laser cleaning machine delivers fast and consistent cleaning performance across different materials and surface conditions. Adjustable parameters such as laser power, pulse frequency, and scanning pattern allow operators to optimize the process for specific contaminants and substrates.

The stable laser output ensures uniform cleaning quality over long operating periods, making the machine suitable for continuous industrial use. Compared with manual or abrasive cleaning methods, laser cleaning significantly reduces cleaning time and improves process repeatability.

Environmentally Friendly and Cost-Effective Operation

Laser cleaning is a dry and eco-friendly process that does not require chemicals, solvents, or consumables. It produces minimal waste, usually limited to fine dust or particles that can be easily collected by a fume extraction system. This eliminates the need for hazardous waste disposal and reduces environmental and regulatory compliance costs.

In addition, the low maintenance requirements of the laser cleaning machine help reduce long-term operating expenses. With no abrasive media or chemical supplies to replace, users benefit from lower consumable costs and simplified maintenance routines.

Wide Range of Cleaning Applications

The laser cleaning machine is suitable for removing a variety of surface contaminants, including:

-

Rust and oxidation layers

-

Paint and surface coatings

-

Oil, grease, and residues

-

Oxide films before welding or bonding

-

Surface contaminants from molds and tools

Its versatility makes it an ideal solution for both production and maintenance applications across multiple industries.

Compatibility with Different Materials

The system can be used on a wide range of base materials without causing damage, including:

-

Carbon steel

-

Stainless steel

-

Aluminum

-

Copper and alloys

-

Other industrial metals

By adjusting laser parameters, the machine can handle different material properties and surface conditions, ensuring effective cleaning while maintaining surface quality.

Integration into Industrial Workflows

The laser cleaning machine can be used as a standalone unit or integrated into automated production lines. Handheld and automated configurations are available to suit different operational needs. For production environments, the system can be combined with robotic arms, conveyor systems, or CNC platforms for high-throughput cleaning tasks.

This flexibility allows manufacturers to incorporate laser cleaning into existing workflows, improving efficiency and consistency without major process changes.

Typical Industry Applications

The laser cleaning machine is widely used in various industries, including:

-

Metal fabrication and surface preparation

-

Automotive manufacturing and maintenance

-

Mold and tool cleaning

-

Pre-welding and pre-coating surface treatment

-

Industrial maintenance and restoration

Its ability to deliver precise, repeatable, and eco-friendly cleaning results makes it a preferred choice for modern industrial applications.

Improved Safety and Operator Convenience

Compared with traditional cleaning methods, laser cleaning improves workplace safety by eliminating exposure to hazardous chemicals and reducing dust and noise. The machine is designed with safety features such as protective enclosures, interlocks, and emergency stop systems to ensure safe operation.

User-friendly controls and intuitive interfaces simplify operation and reduce training time, allowing operators to achieve optimal results quickly.

Conclusion

The laser cleaning machine provides an efficient, non-contact, and environmentally friendly solution for industrial surface cleaning. By removing rust, paint, oil, coatings, and contaminants without damaging the base material, it delivers consistent and high-quality results. With stable performance, low maintenance, and wide application compatibility, this machine is an ideal choice for metal fabrication, automotive, mold cleaning, and industrial surface preparation.

Frequently Asked Questions

1. What is the most important factor when choosing a laser welder?

The two most important factors are material thickness and usage scenario. Material thickness determines the required laser power, while the application scenario determines whether you need a handheld, workstation, or automated laser welding system.

2. How does material thickness affect laser welder selection?

Laser power must match the thickness of the material to ensure proper penetration and weld strength.

- 0.5–3 mm: Low to medium power laser welders are suitable for thin sheet metal and precision parts.

- 3–6 mm: Medium power laser welders are ideal for general fabrication and industrial components.

- 6 mm and above: High-power laser welders are recommended for structural parts and heavy-duty welding.

Choosing insufficient power may cause weak welds, while excessive power can lead to burn-through on thin materials.

3. Can one laser welder handle different thicknesses?

Yes. Most modern laser welders offer adjustable power settings, allowing them to handle a range of thicknesses. However, the base laser power should always be selected according to the most common thickness used in daily production.

4. How does the welding scenario influence the choice?

- Handheld laser welding: Best for flexible jobs, repairs, small batches, and irregular workpieces.

- Workshop or production welding: Suitable for repeated welding of standard parts with consistent thickness.

- Industrial or heavy-duty welding: Requires higher power, stable cooling, and often automated systems for continuous operation.

5. Does material type matter in addition to thickness?

Yes. Materials like stainless steel and carbon steel weld easily, while aluminum and copper reflect more laser energy and usually require higher power or optimized parameters, even at the same thickness.

6. Is higher laser power always better?

No. Higher power increases penetration but also raises cost and the risk of overheating thin materials. The best choice is a laser welder that matches your actual thickness range and application needs, not simply the highest wattage available.

7. What other features should I consider?

In addition to laser power, consider:

- Cooling system stability

- Welding head control and ergonomics

- Safety features and ease of operation

- Suitability for continuous or intermittent use

These factors directly affect long-term welding quality and productivity.

Summary

To choose the right laser welder, start with material thickness, then match it with your welding scenario. A properly selected laser welder delivers stable penetration, clean welds, and higher efficiency without unnecessary cost.

1. What is the first thing to consider when choosing a laser cleaning machine?

Start by identifying your cleaning needs: the type of material (metal, plastic, rubber), the kind of contaminants (rust, paint, oil), and the size of surfaces you will clean most often. Matching machine specs to these requirements is essential for effective cleaning.

2. How does laser power affect the choice?

Laser power determines how fast and effectively contaminants are removed:

- Low power (20–200W): Suitable for delicate surfaces, light rust, thin paint, or precision tasks.

- Medium power (200–500W): Ideal for general cleaning of rust, grease, and paint on moderate-sized parts.

- High power (500W+): Best for heavy-duty cleaning on thick coatings and large surfaces in industrial environments.

Choose the lowest power that safely handles your hardest cleaning task to avoid surface damage and excessive cost.

3. Should I choose handheld or stationary?

Handheld machines are great for flexible on-site cleaning, repairs, and variable workpieces. Stationary units or automated systems suit high-volume production, assembly lines, or fixed cleaning stations.

4. Is wavelength important?

Yes. The laser wavelength affects how well energy is absorbed by the material:

-

Fiber lasers (~1064 nm): Common for most metal cleaning.

-

CO₂ lasers (~10.6 µm): Often better for non-metal materials like plastics or wood.

Matching wavelength to material improves cleaning efficiency and reduces heat damage.

5. What about pulse type and frequency?

Laser cleaners can operate in pulsed or continuous modes:

-

Pulsed lasers: Deliver bursts of energy, reducing heat impact — ideal for precision cleaning and sensitive surfaces.

-

Continuous wave lasers: Provide steady output, useful for bulk contaminant removal where thermal impact is less critical.

Pulse frequency and duration influence how aggressively contaminants are removed without harming the substrate.

6. How does production volume influence my choice?

-

Small batches or occasional use: Compact or portable systems work best.

-

Continuous high throughput: Fixed or automated laser cleaning machines with robust cooling and duty cycles improve productivity.

Always consider how much cleaning your operation requires over time.

7. What safety and support features should I look for?

Ensure the machine has proper safety measures (interlocks, shielding), cooling systems to manage heat, and quality support from the supplier for training, maintenance, and repairs. Good safety design and after-sales service reduce risk and downtime.

8. Do I need to consider long-term costs?

Yes — look beyond the purchase price. Factor in operational costs like energy consumption, maintenance, consumables (filters, optics), and downtime costs. A machine that is inexpensive upfront but costly to maintain can reduce overall value.

9. Is testing important before buying?

Absolutely. Testing with your materials and contaminant types helps verify cleaning speed, power sufficiency, and surface impact. This practical step prevents mismatches between specifications and real-world performance.

10. What’s the best way to balance performance and cost?

Choose a machine that meets your heaviest cleaning need without over-specifying. For most general industrial tasks, a mid-range power laser cleaner (200–500W) balances cost, flexibility, and capability. For specialized tasks, adjust power, configuration, and automation accordingly.