Handheld Laser Welder: Complete Guide to Laser Welding Technology, Applications, and Price Factors

News 2022-06-14

Introduction: Why Handheld Laser Welders Are Changing the Welding Industry

In recent years, the handheld laser welder has rapidly gained attention across manufacturing, repair, and fabrication industries. Compared with traditional welding methods such as MIG, TIG, or arc welding, laser weld technology offers faster speeds, cleaner weld seams, lower heat input, and significantly reduced post-processing requirements.

As labor costs rise and production efficiency becomes more critical, more workshops and factories are exploring laser welding as a practical alternative. At the same time, discussions about laser welder price, performance differences, and long-term value have become increasingly common.

This guide provides a complete, practical overview of handheld laser welders—how they work, where they are used, their advantages and limitations, and what really determines laser welder pricing.

What Is a Handheld Laser Welder?

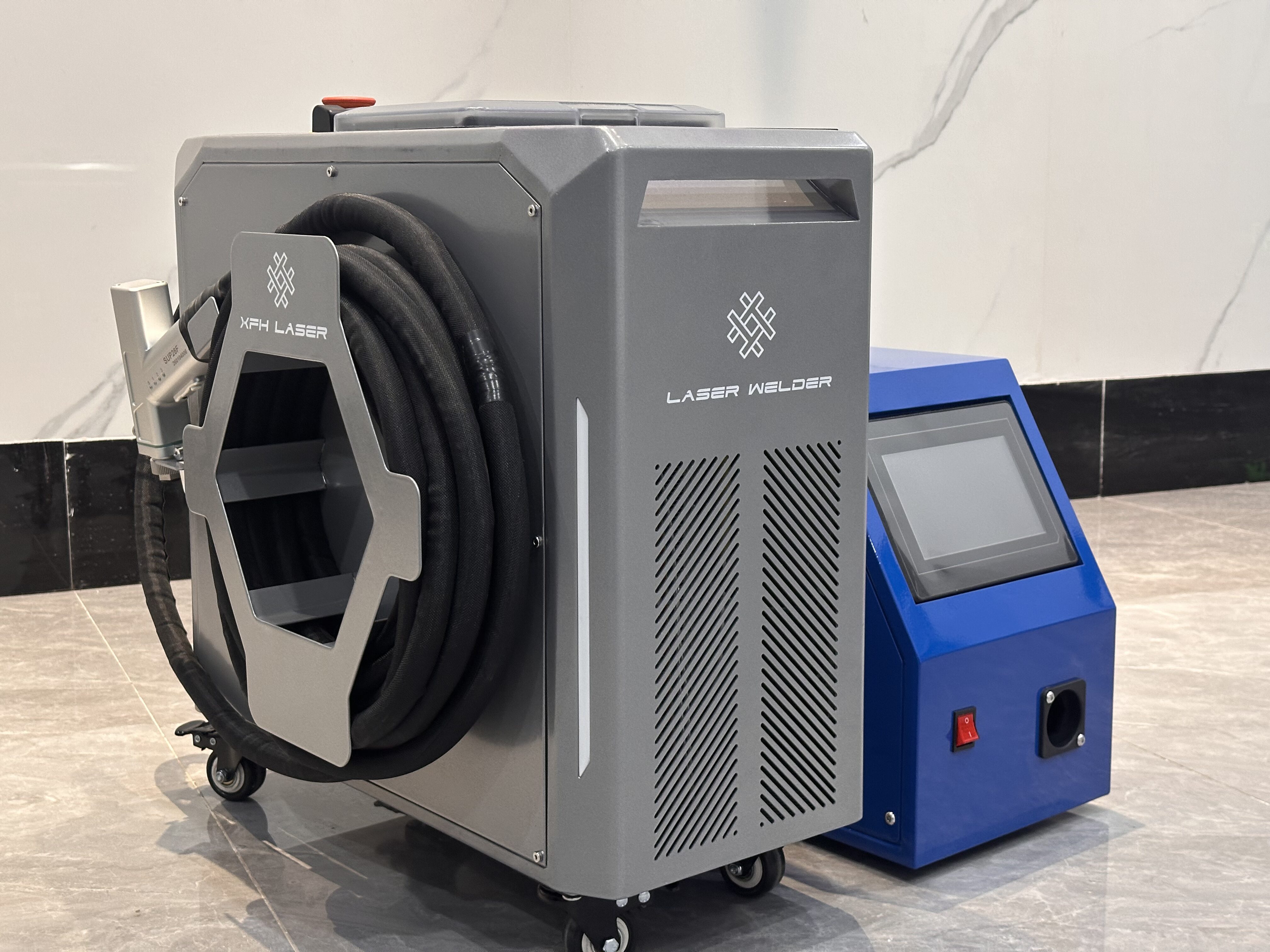

A handheld laser welder is a portable laser welding system that allows operators to manually guide a laser welding head to join metal parts. Unlike large fixed laser welding stations, handheld systems emphasize flexibility, mobility, and ease of use.

Basic Definition

- Uses a high-energy laser beam to melt and fuse metals

- Operated manually with a handheld welding gun

- Suitable for thin to medium-thickness materials

- Designed for flexibility rather than full automation

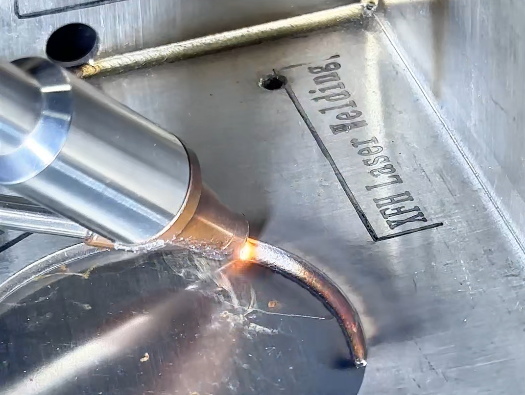

How Laser Weld Technology Works

Laser weld systems focus a high-density laser beam onto a small area of the workpiece. This concentrated energy rapidly heats the metal, forming a molten pool that solidifies into a strong, precise weld seam.

Key characteristics of laser weld processes include:

- Extremely small heat-affected zone

- High penetration depth with minimal distortion

- Clean weld seams with low spatter

Key Components of a Handheld Laser Welding System

Understanding the main components helps buyers better evaluate system quality and laser welder price differences.

Laser Source

The laser source determines output power, stability, and welding capability. Power levels typically range from low to high depending on material thickness and production needs.

Handheld Welding Gun

The ergonomic design of the handheld laser welder gun affects operator comfort, precision, and productivity. Modern designs prioritize lightweight construction and intuitive controls.

Cooling System

Laser welding generates significant heat. Efficient cooling systems ensure stable laser output and long service life, especially for continuous operation.

Control System

Advanced control systems allow precise adjustment of parameters such as power, frequency, and welding mode, making it easier to adapt to different materials and weld joints.

Laser Weld vs Traditional Welding Methods

One of the most common questions is whether a handheld laser welder can truly replace traditional welding processes.

Advantages of Laser Welding

Laser weld technology offers several distinct advantages:

- Faster welding speed

- Minimal deformation and warping

- Clean weld seams with little or no grinding

- Lower consumable usage

- Easier learning curve for new operators

Limitations to Consider

Despite its advantages, laser welding is not a universal solution:

- Higher initial investment compared to basic welding machines

- Requires proper safety training and protection

- Not always ideal for very thick materials without preparation

Typical Applications of Handheld Laser Welders

The versatility of handheld laser welders makes them suitable for a wide range of industries.

Metal Fabrication and Sheet Metal Processing

Laser welding is ideal for stainless steel, carbon steel, aluminum, and galvanized sheets commonly used in:

- Cabinets and enclosures

- Doors and windows

- Kitchen equipment

- Decorative metal products

Automotive Repair and Maintenance

In automotive workshops, handheld laser welders are used for:

- Body panel repairs

- Precision welding of thin metal parts

- Reduced heat damage to surrounding components

Machinery and Equipment Manufacturing

Manufacturers benefit from laser weld precision when assembling:

- Mechanical housings

- Structural components

- Custom metal parts

Maintenance, Repair, and Custom Work

The portability of handheld laser welders makes them especially useful for:

- On-site repairs

- Mold and tool maintenance

- Small-batch custom fabrication

Laser Weld Quality and Performance Factors

Achieving consistent laser weld quality depends on several technical and operational factors.

Material Type

Different metals respond differently to laser energy. Common laser weld materials include:

Stainless steel

Carbon steel

Aluminum alloys

Copper and brass (with proper parameters)

Material Thickness

Handheld laser welders are particularly effective for thin to medium-thickness materials, where precision and low heat input are critical.

Welding Parameters

Proper adjustment of power, speed, and focus is essential for achieving strong and visually clean weld seams.

Laser Welder Price: What Determines the Cost?

One of the most searched topics is laser welder price, and for good reason. Prices vary widely depending on system configuration and intended use.

General Laser Welder Price Ranges

While prices vary by market and configuration, handheld laser welder systems typically fall into these broad categories:

- Entry-level systems: suitable for light-duty work and repairs

- Mid-range systems: balanced performance for workshops and small factories

- Industrial-grade systems: designed for continuous operation and demanding production environments

Key Price Influencing Factors

Laser Power

Higher power levels generally increase laser welder price but also expand welding capabilities.

System Stability and Lifespan

High-quality components and cooling systems contribute to long-term reliability and reduced maintenance costs.

Control and Automation Features

Advanced interfaces and parameter presets improve productivity and reduce operator error.

After-Sales Support

Technical support, training, and spare parts availability add long-term value beyond the initial purchase price.

Is a Handheld Laser Welder Worth the Investment?

When evaluating laser welder price, it is important to consider total cost of ownership rather than just upfront cost.

Cost Savings Over Time

- Reduced labor hours

- Less post-weld finishing

- Lower consumable expenses

- Faster job turnaround

Productivity Gains

Laser weld speed and ease of use allow operators to complete more work in less time, improving overall profitability.

Safety Considerations for Laser Welding

Safety is critical when using any laser weld system.

Eye and Skin Protection

Operators must use appropriate laser safety glasses and protective clothing to prevent injury.

Work Environment

Proper shielding, ventilation, and workspace layout help reduce risks associated with laser reflection and fumes.

Training

Adequate operator training ensures consistent weld quality and safe operation.

Common Misconceptions About Handheld Laser Welders

“Laser Welders Are Too Complicated”

Modern handheld laser welders are designed with user-friendly controls, making them accessible even to operators with limited welding experience.

“Laser Welding Is Only for High-End Factories”

With decreasing laser welder prices and improved portability, laser welding is now practical for small workshops and repair businesses.

Future Trends in Laser Weld Technology

Laser welding technology continues to evolve, with trends including:

- Increased energy efficiency

- Smarter control systems

- Integration with automation and robotics

- Wider adoption in small and medium-sized enterprises

As technology advances, handheld laser welders are expected to become even more versatile and cost-effective.

Conclusion: Choosing the Right Handheld Laser Welder

A handheld laser welder represents a powerful tool for modern metalworking, combining flexibility, precision, and efficiency. While laser welder price can vary significantly, the long-term benefits of laser weld technology often outweigh the initial investment.

By understanding how handheld laser welders work, where they are best applied, and what factors influence pricing, buyers can make informed decisions that match their production needs and budget.

For manufacturers, fabricators, and repair professionals seeking cleaner welds, faster workflows, and higher productivity, handheld laser welding is no longer a future concept—it is a practical solution available today.