Laser Cutting Machines: Transforming Modern Manufacturing

News 2022-06-14

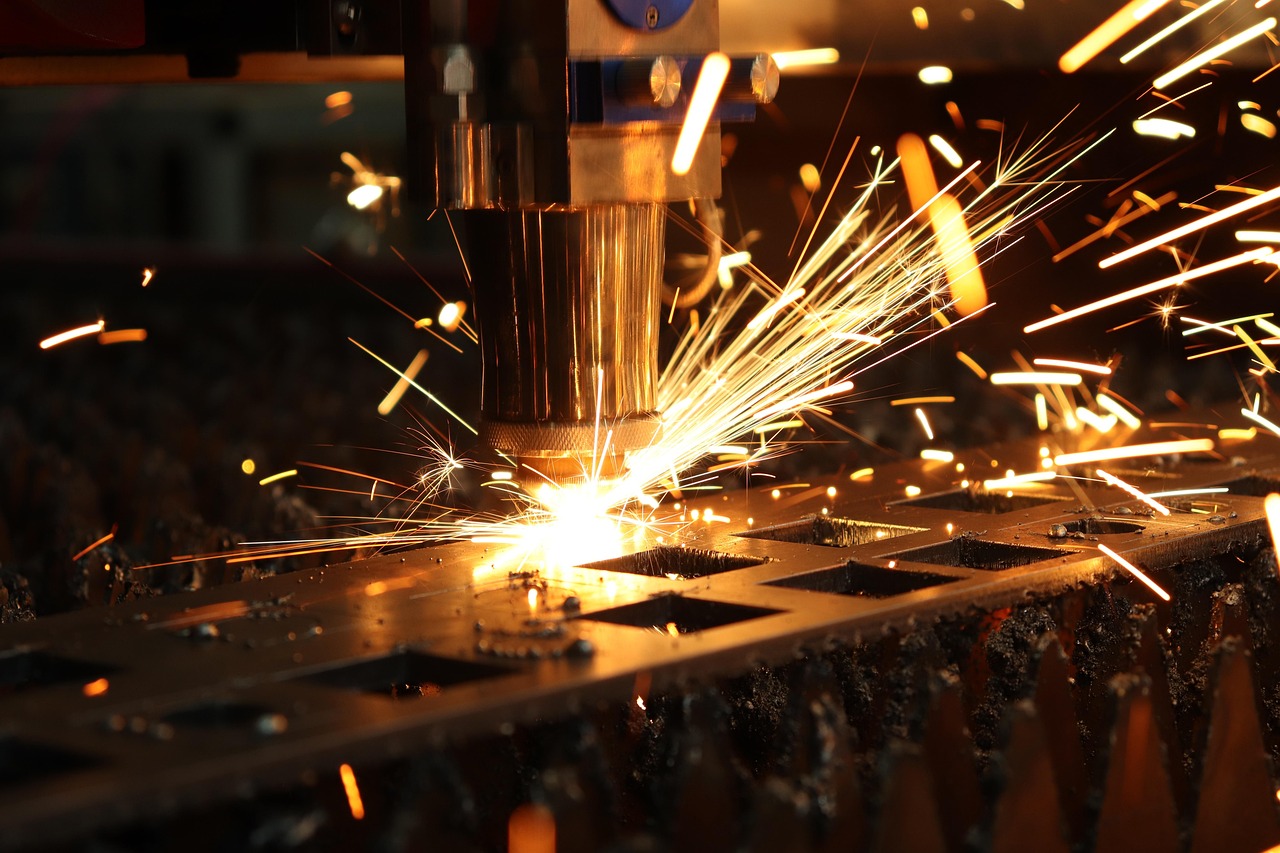

In today’s fast-paced manufacturing world, precision, speed, and versatility are critical for staying competitive. One technology that has revolutionized production across industries is the laser cutting machine. From industrial fabrication to small workshops and creative projects, laser cutting machines are now indispensable tools. With their ability to cut metals, plastics, acrylics, wood, and other materials, they provide a level of precision and efficiency that traditional cutting methods struggle to achieve.

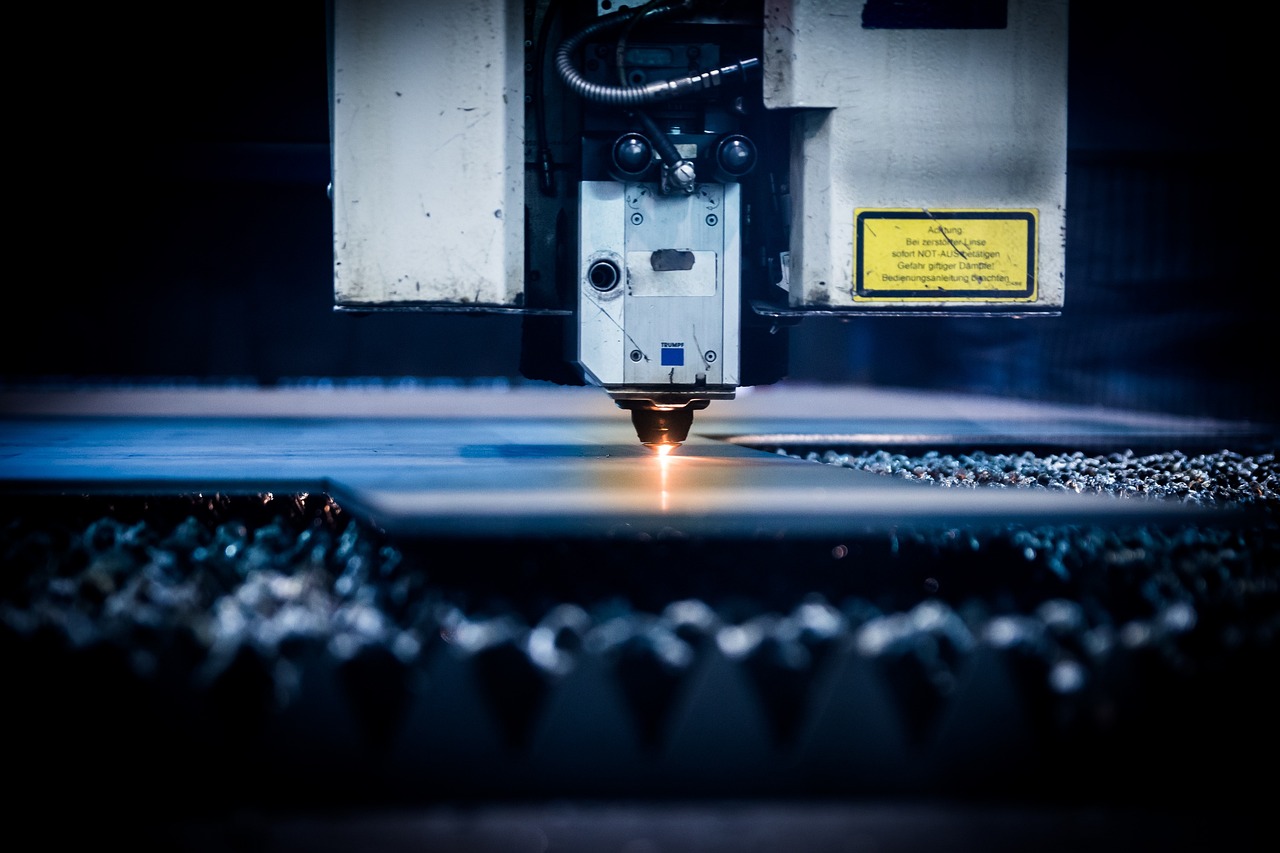

Modern laser cutting machines combine high-power lasers with CNC control systems, allowing operators to create complex designs with exceptional accuracy. Unlike mechanical cutting, laser systems offer clean edges, minimal heat-affected zones, and faster production speeds, making them ideal for both high-volume industrial production and specialized custom projects.

Whether you are in the metalworking industry, furniture manufacturing, automotive repair, or prototyping, investing in a high-quality laser cutting machine can dramatically improve workflow and output quality.

How Laser Cutting Machines Work

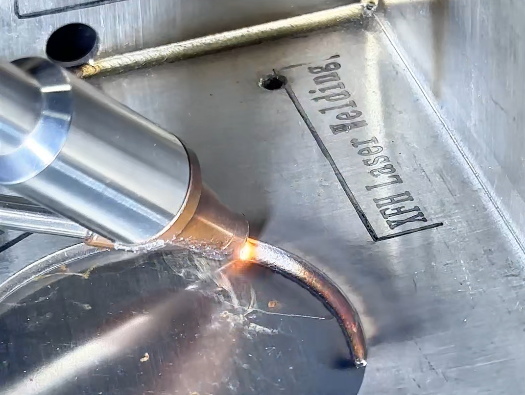

A laser cutting machine operates by focusing a high-powered laser beam onto a material’s surface. The laser melts, burns, or vaporizes the material, leaving behind a precise cut. The process is usually controlled by a CNC (Computer Numerical Control) system, which guides the laser according to the design file.

There are several types of lasers commonly used in cutting machines:

- CO₂ lasers: Ideal for non-metal materials like wood, acrylic, leather, and plastics.

- Fiber lasers: Perfect for metals such as stainless steel, aluminum, copper, and brass. Fiber lasers are highly efficient and provide superior edge quality.

- Diode lasers: Often used for smaller, lower-power applications or engraving purposes.

The CNC system allows the operator to input a digital design, and the machine follows the exact path with high accuracy. The combination of CNC control and laser technology ensures clean edges, minimal material wastage, and consistent results across large production batches.

Applications of Laser Cutting Machines

The versatility of laser cutting machines makes them suitable for a wide range of applications:

1. Metal Fabrication

Industries such as automotive, aerospace, and machinery rely heavily on precision metal cutting. Fiber laser cutting machines are capable of cutting metals with extreme accuracy, creating parts that require minimal finishing.

2. Wood and Acrylic Projects

For furniture makers, signage manufacturers, and decorative panel producers, CO₂ laser cutting machines provide clean cuts and intricate designs that would be difficult to achieve with traditional tools. Acrylic sheets, plywood, MDF, and other materials can be shaped with precision and minimal effort.

3. Automotive and Aerospace Components

Laser cutting ensures tight tolerances, consistent cuts, and repeatable results—critical for parts that need to meet strict engineering standards. Components like chassis parts, brackets, and interior panels benefit from the precision offered by industrial laser cutting machines.

4. DIY, Prototyping, and Hobby Use

Smaller desktop laser cutters have made it possible for hobbyists and small businesses to create prototypes, models, and custom products. With these machines, complex patterns, engravings, and designs can be achieved in a fraction of the time compared to manual methods.

Advantages of Using Laser Cutting Machines

Investing in a laser cutting machine brings several advantages over traditional cutting methods:

- High Precision and Repeatability: Laser beams can cut with micrometer-level accuracy, producing consistent results across multiple pieces.

- Faster Production Speeds: Laser cutting is often faster than mechanical cutting, especially for intricate designs.

- Minimal Material Waste: The focused laser beam reduces the kerf width and heat-affected zones, resulting in more efficient use of material.

- Complex Design Capability: Lasers can cut intricate shapes, curves, and patterns that would be difficult or impossible with conventional tools.

- Enhanced Safety: Many laser cutting machines come with enclosed systems, reducing exposure to fumes, sparks, and sharp edges.

These advantages make laser cutting machines an excellent choice for both small and large-scale manufacturing, increasing efficiency and reducing production costs.

Choosing the Right Laser Cutting Machine

Selecting the right laser cutting machine depends on several factors:

- Material Type and Thickness: Determine if you primarily cut metals, plastics, wood, or acrylic. Fiber lasers excel at metal cutting, while CO₂ lasers are better for non-metals.

- Laser Type and Power: Higher wattage provides faster cutting speeds and the ability to cut thicker materials.

- Cutting Precision and Resolution: CNC-controlled lasers provide consistent results and enable detailed design work.

- Workspace Size: Consider the maximum sheet size the machine can handle.

- Budget and Maintenance Costs: Evaluate the upfront cost versus long-term efficiency gains and maintenance requirements.

It is also important to consider laser cutting machine price in relation to its features. Investing in a slightly higher-end machine with better stability, precision, and reliability often pays off in reduced downtime and higher-quality output.

Laser Cutting vs. Traditional Cutting Methods

Compared to traditional cutting methods such as mechanical saws, plasma cutting, or waterjet cutting, laser cutting machines offer unique advantages:

- Precision: Lasers can achieve extremely fine cuts and intricate shapes that mechanical tools cannot.

- Speed: Complex cuts are faster with a laser, reducing production time.

- Clean Edges: Minimal finishing is required due to the smooth cut edges.

- Reduced Material Deformation: Lasers apply localized heat, reducing distortion and maintaining material integrity.

- Versatility: Capable of cutting metals, plastics, wood, fabrics, and more without changing tools.

While traditional cutting methods still have their place for very thick or rough material cutting, the precision, speed, and flexibility of laser cutting make it the preferred choice in most modern manufacturing scenarios.

The Future of Laser Cutting Machines

The future of laser cutting machines is promising, with technological advancements driving smarter, faster, and more eco-friendly production:

- AI-assisted cutting: Optimizes paths and reduces waste for maximum efficiency.

- Automation integration: Fully automated production lines reduce labor costs and increase throughput.

- Hybrid laser systems: Combining cutting, engraving, and marking in a single machine.

- Sustainability: Reduced energy consumption and minimal material waste make laser cutting more environmentally friendly.

As industries embrace Industry 4.0, laser cutting machines will continue to play a critical role in smart factories, mass customization, and innovative product design.

Conclusion

Laser cutting machines have transformed modern manufacturing by providing unmatched precision, speed, and versatility. From industrial metal fabrication to creative woodworking and acrylic projects, these machines offer solutions that traditional cutting tools simply cannot match.

Investing in a high-quality laser cutting machine improves workflow efficiency, ensures consistent results, and opens new possibilities for complex designs. Whether you are an industrial manufacturer, a small business owner, or a hobbyist, incorporating laser cutting technology into your workflow is a smart move toward higher productivity and superior quality.

Explore the right laser cutting machine for your needs and unlock the full potential of precision manufacturing.