XFH Laser Cutting Machine

Product Category:

Laser Cutting Machine

Power Options:

Customizable (1000W/1500W/2000W/3000W)

Bed Size:

Customizable (Standard: 3050mm×1525mm)

Sales Hotline:

+86 189 5604 0458

Email:

alan@xfhlaser.com

Various power laser options available, customizable bed size. Bed with annealing treatment, stable and deformation-free. Drive system uses internationally renowned brands. Intelligent drawing system, simple and easy to learn.

Product Introduction

The XFH Laser Cutting Machine is equipped with the latest laser cutting technology, capable of high-precision, high-speed cutting of various materials. The bed is annealing treated to ensure stability and prevent deformation, while the transmission system uses internationally renowned brands to ensure reliable performance. The intelligent drawing system is simple and easy to learn.

Product Features

Latest Cutting System: Uses advanced technology to ensure optimal cutting performance and results.

Renowned Brand Components: Uses internationally renowned brands to ensure reliability and durability.

Customizable: Flexible power options and bed sizes to meet specific requirements.

High Precision: Provides precise cutting for complex designs and patterns.

Fast Cutting: Efficient operation for increased productivity and capacity.

Easy to Learn: Intelligent drawing system with user-friendly interface.

Advantages

Stable Bed Structure: Annealing treatment ensures the bed remains stable during long-term operation, without deformation.

Quality Components: Transmission system uses internationally renowned brands, ensuring reliability and longevity.

Customization Options: Can be equipped with different power laser options and bed sizes to meet various production needs.

Intelligent Control: Advanced drawing system simplifies operation, reducing learning curve.

Versatile Applications: Suitable for cutting various materials, including metals, acrylic, wood, etc.

High Efficiency: Fast cutting speed increases production capacity and reduces costs.

Technical Specifications

Parameter Specification

Laser Type Fiber Laser

Laser Power Optional: 1000W/1500W/2000W/3000W

Bed Size Customizable (Standard: 3050mm×1525mm)

Bed Treatment Full bed annealing treatment, stable and deformation-free

Cutting Precision ±0.05mm

Repeated Positioning Accuracy ±0.03mm

Maximum Cutting Thickness Carbon Steel: 20mm / Stainless Steel: 12mm / Aluminum: 8mm

Transmission System Internationally Renowned Brands

Control System Intelligent Drawing System, Simple and Easy to Learn

Cooling System Water Cooling

Power Supply 380V / 50Hz Three-phase Five-wire

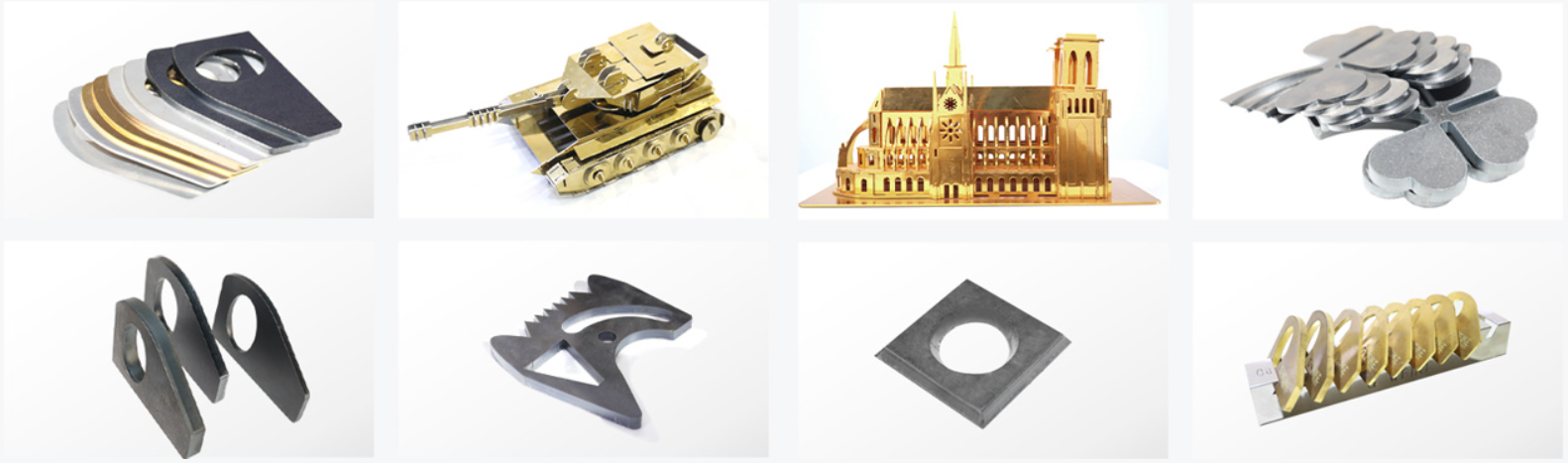

Application Areas

Metal Processing

Main Applications: Precision metal parts processing, sheet metal manufacturing, industrial component production.

Applicable Materials: Carbon steel, stainless steel, aluminum alloy, galvanized sheet, copper plate, etc.

Typical Thickness: Carbon steel up to 20mm, stainless steel up to 12mm, aluminum up to 8mm.

Advantages: High cutting precision, smooth edges, small heat affected zone, minimal deformation, high production efficiency.

Automotive Manufacturing

Main Applications: Body panels, chassis brackets, structural components, interior parts.

Features: High-precision cutting ensures precise fit of automotive parts, improving assembly efficiency.

Applicable Scenarios: Prototype design, small batch production and customized production.

Advantages: Quick mold change, high processing flexibility, no mold required, reduced production costs.

Machinery Manufacturing

Main Applications: Gears, bearing housings, hydraulic components, mechanical frame structures.

Features: Can achieve complex contour cutting to meet high precision requirements.

Processing Capabilities: Can cut complex shapes, including small holes, slits, and detailed features.

Advantages: Shortened production cycle, reduced downstream processing steps, decreased production costs.

Electronics Manufacturing

Main Applications: Electronic device enclosures, control cabinet panels, precision electronic components.

Features: Can meet high precision, small hole diameter, thin sheet cutting requirements.

Typical Materials: Aluminum alloy, stainless steel thin sheets, galvanized sheets, etc.

Advantages: Smooth cutting edges, burr-free, reduced post-processing steps, ensuring product appearance.

Customer Success Stories

“After introducing the XFH laser cutting machine to our company, production efficiency increased by 40%, and the defect rate dropped from 5% to less than 1%. Most importantly, the operating system is very user-friendly, greatly shortening the training time for new employees.”

“As a custom signage manufacturer, the precision of the XFH laser cutting machine allows us to take on more intricate projects. The intelligent drawing system is easy to learn, and we were able to operate normally within days of installation. This equipment has created new business opportunities for us.”